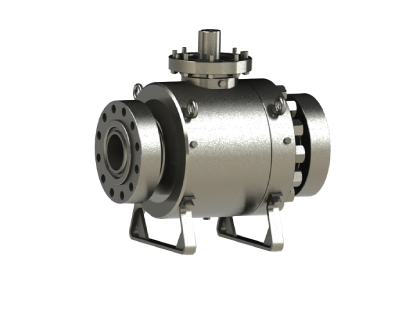

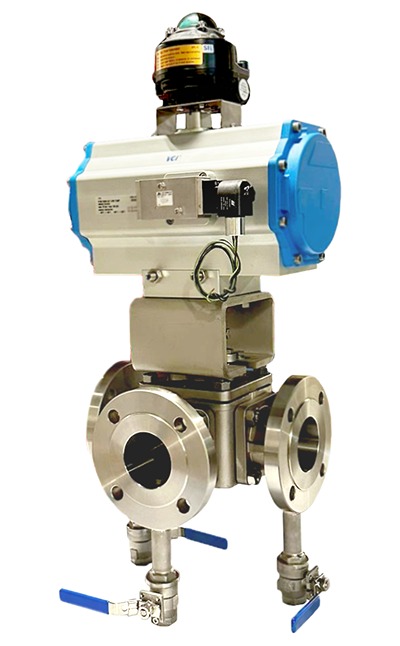

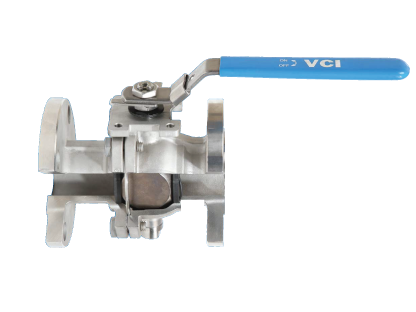

GVS Welded Body Trunnion Mounted Ball Valves are used in the energy industry where high-integrity, maintenance-free isolation is essential, particularly in buried pipelines, high-pressure natural gas transmission, and remote compressor or pump stations. Their fully welded body design eliminates external leak paths, making them ideal for underground installations and power generation fuel systems where safety, durability, and long service life are critical. These valves are commonly used in both conventional and renewable energy infrastructure, offering robust performance in demanding environments with minimal need for servicing.

- Buried Pipelines: Provide long-term, leak-proof isolation in underground energy transmission lines with zero external bolting.

- High-Pressure Natural Gas Transmission: Ensure safe, maintenance-free shut-off in long-distance gas pipelines operating at elevated pressures.

- Remote Compressor Stations: Deliver robust, tamper-resistant valve performance in isolated energy transport hubs with limited access for servicing.

- Pump Stations: Maintain secure flow control and minimize fugitive emissions in high-volume liquid transport systems.

- Power Generation Fuel Systems: Safeguard continuous fuel supply to turbines or boilers with high-integrity isolation in both conventional and renewable power plants.

Les vannes à boisseau sphérique à corps soudé, montées sur tourillon GVS, sont utilisées dans l’industrie de l’énergie là où une isolation sans entretien et à haute intégrité est essentielle, notamment dans les canalisations enterrées, le transport de gaz naturel à haute pression, et les stations de compression ou de pompage éloignées. Leur conception entièrement soudée élimine tous les risques de fuite externe, ce qui les rend idéales pour les installations souterraines et les systèmes d’alimentation en combustible des centrales électriques où la sécurité, la durabilité et la longévité sont primordiales. Ces vannes sont couramment utilisées dans les infrastructures énergétiques conventionnelles et renouvelables, offrant des performances robustes dans des environnements exigeants avec un minimum de maintenance.

- Canalisations enterrées : Isolation durable et étanche pour les lignes de transmission d’énergie souterraines sans aucun boulon externe.

- Transport de gaz naturel à haute pression : Coupure sûre et sans entretien dans les gazoducs longue distance à pression élevée.

- Stations de compression éloignées : Performances robustes et anti-sabotage dans les hubs de transport énergétique difficiles d’accès.

- Stations de pompage : Contrôle fiable du débit et minimisation des émissions fugitives dans les systèmes de transport de liquides à grand volume.

- Systèmes d’alimentation des centrales : Sécurisent l’alimentation en combustible des turbines ou chaudières grâce à une isolation à haute intégrité, dans les centrales classiques et renouvelables.

GVS Welded-Body, Trunnion-Mounted Ball Valves are used in Oil & Gas applications where leak prevention, structural integrity, and maintenance-free operation are critical. They are commonly installed in buried natural gas transmission pipelines, compressor and pump stations, and block valve stations, where external bolting and potential leak paths must be eliminated. The fully welded body design offers superior strength and resistance to vibration, pressure, and harsh environments, making these valves ideal for long-term, high-reliability service in midstream and transmission infrastructure.

- Buried Natural Gas Transmission Pipelines: Provide leak-free, maintenance-free isolation with a fully welded body ideal for underground installation.

- Compressor and Pump Stations: Deliver robust shut-off and vibration-resistant performance in high-pressure boosting systems.

- Block Valve Stations: Offer secure sectional isolation in long-distance pipelines with minimal external exposure and reduced maintenance needs.

- Metering and Regulator Stations: Maintain high sealing integrity and pressure containment at key flow control and measurement points.

Les vannes à boisseau sphérique à corps soudé, montées sur tourillon GVS, sont utilisées dans le secteur Oil & Gas là où la prévention des fuites, l’intégrité structurelle et le fonctionnement sans maintenance sont essentiels. Elles sont couramment installées dans les gazoducs enterrés, les stations de compression et de pompage, ainsi que les stations de sectionnement, là où tout boulonnage externe et tout risque de fuite doivent être éliminés. Leur conception à corps entièrement soudé offre une résistance supérieure aux vibrations, à la pression et aux environnements difficiles, ce qui en fait une solution idéale pour un service longue durée et une fiabilité élevée dans les infrastructures de transport.

- Gazoducs enterrés : Isolation sans fuite et sans entretien grâce à un corps totalement soudé, parfait pour l’installation souterraine.

- Stations de compression et de pompage : Coupure robuste et résistance aux vibrations dans les systèmes de surpression haute pression.

- Stations de sectionnement : Isolation sûre par section dans les pipelines longue distance, avec exposition externe minimale et maintenance réduite.

- Stations de comptage et de régulation : Maintien d’une étanchéité optimale et de la pression dans les points de contrôle et de mesure des flux.