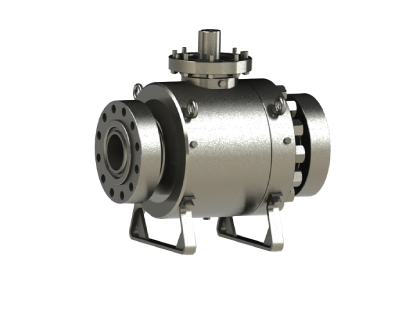

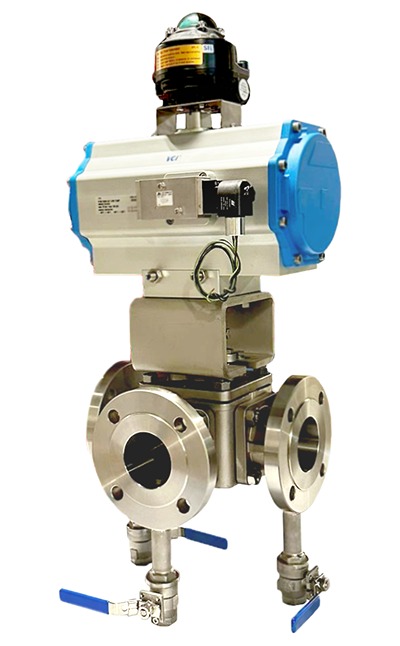

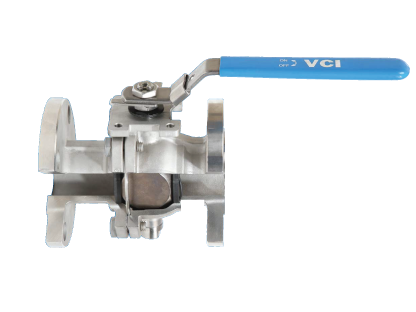

GVS Metal-Seated Trunnion Mounted Ball Valves are used in the petrochemical industry where high temperatures, abrasive media, or corrosive fluids make soft-seated valves unsuitable. These valves are commonly deployed in catalytic reformers, delayed coking units, high-temperature gas or slurry lines, and chemical reactors, where they withstand thermal cycling, erosive particles, and aggressive chemicals. Their hard-faced sealing surfaces and robust construction ensure long-term performance and leak-tight isolation in severe service environments typical of petrochemical processing plants.

- Catalytic Reformers: Withstand high temperatures and corrosive reformate streams while maintaining tight shut-off in continuous processing.

- Delayed Coking Units: Provide reliable sealing in abrasive, high-temperature environments where coke particles and heavy residues are present.

- High-Temperature Gas Lines: Ensure leak-free isolation of process gases in extreme heat conditions where soft seats would degrade.

- Slurry Transport Lines: Handle erosive flow containing catalysts or solid-laden fluids with durable, wear-resistant sealing surfaces.

- Chemical Reactors: Operate under severe chemical exposure and thermal stress, delivering consistent performance in demanding batch or continuous processes.

- Steam and Condensate Lines: Control flow in utility systems supporting petrochemical processes where high-temperature cycling is frequent.

Les vannes à boisseau sphérique à siège métallique GVS sont utilisées dans l’industrie pétrochimique là où des températures élevées, des fluides abrasifs ou corrosifs rendent les vannes à siège souple inadaptées. Elles sont couramment installées sur les reformeurs catalytiques, les unités de cokéfaction différée, les lignes de gaz ou de boues à haute température et les réacteurs chimiques, où elles résistent aux cycles thermiques, aux particules érosives et aux produits chimiques agressifs. Leur construction robuste et leurs surfaces d’étanchéité renforcées garantissent des performances durables et une isolation sans fuite dans les environnements sévères des usines pétrochimiques.

- Reformeurs catalytiques : Résistent aux hautes températures et aux flux corrosifs tout en assurant une fermeture étanche en continu.

- Unités de cokéfaction différée : Assurent l’étanchéité dans des environnements abrasifs à haute température, avec présence de coke et résidus lourds.

- Lignes de gaz haute température : Offrent une isolation parfaite des gaz de process en conditions de chaleur extrême, là où les sièges souples échoueraient.

- Lignes de transport de boues : Supportent les flux érosifs avec catalyseurs ou solides grâce à des surfaces d’étanchéité résistantes à l’usure.

- Réacteurs chimiques : Fonctionnent sous forte exposition chimique et contraintes thermiques, avec des performances constantes en process batch ou continu.

- Lignes de vapeur et de condensat : Contrôlent les flux dans les utilités des process pétrochimiques soumis à de nombreux cycles thermiques.

GVS Metal-Seated, Trunnion-Mounted Ball Valves are used in Oil & Gas applications where soft-seated valves would fail due to abrasive media, high temperatures, or contaminated fluids. These valves are commonly found in refineries, gasification plants, offshore platforms, and oil sands operations, where they handle catalyst slurries, sour gas, steam, and solid-laden hydrocarbons. Their robust construction and hard-faced sealing surfaces provide reliable performance and long service life in severe service environments that demand high cycle durability and resistance to erosion and corrosion.

- Refineries: Handle high-temperature hydrocarbon streams and abrasive catalysts in processes such as catalytic cracking and coking units.

- Gasification Plants: Provide tight shut-off and erosion resistance in high-pressure, high-temperature environments with particulate-laden syngas.

- Offshore Platforms: Operate in corrosive, high-pressure environments where durability and resistance to sand, scale, and sour gas are essential.

- Oil Sands Operations: Withstand erosive slurry and heavy crude with entrained solids in upstream production and separation processes.

- Sour Gas Processing Facilities: Offer corrosion-resistant sealing in hydrogen sulfide-rich environments where soft seats would degrade rapidly.

- Steam Injection Systems: Control high-pressure steam in enhanced oil recovery (EOR) applications, requiring metal seating to maintain integrity under thermal cycling.

Les vannes à boisseau sphérique à siège métallique GVS sont utilisées dans l’Oil & Gas là où les sièges souples échouent face aux fluides abrasifs, hautes températures ou contaminants. Elles sont présentes dans les raffineries, usines de gazéification, plateformes offshore et exploitations de sables bitumineux, pour traiter boues catalytiques, gaz acide, vapeur et hydrocarbures chargés de solides. Leur construction robuste et leurs surfaces d’étanchéité renforcées assurent des performances fiables et une grande longévité même dans les environnements de service sévères nécessitant endurance, résistance à l’érosion et à la corrosion.

- Raffineries : Traitent les flux d’hydrocarbures à haute température et catalyseurs abrasifs dans le craquage catalytique ou la cokéfaction.

- Usines de gazéification : Assurent l’étanchéité et la résistance à l’érosion sous haute pression/température, avec des gaz de synthèse chargés en particules.

- Plateformes offshore : Fonctionnent dans des environnements corrosifs et sous haute pression, là où la résistance au sable, tartre et gaz acide est cruciale.

- Sables bitumineux : Résistent à la boue abrasive et aux bruts lourds chargés de solides dans la production et séparation amont.

- Usines de traitement du gaz acide : Garantissent l’étanchéité dans les environnements riches en H₂S où les sièges souples se détériorent rapidement.

- Systèmes d’injection de vapeur : Contrôlent la vapeur haute pression dans la récupération assistée du pétrole (EOR) nécessitant un siège métallique résistant aux cycles thermiques.