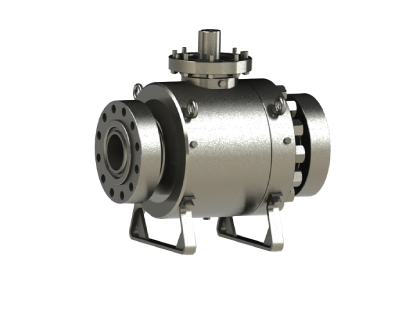

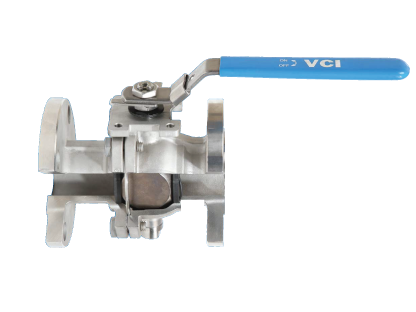

GVS API 6D Soft-Seated Trunnion-Mounted Ball Valves are widely used in midstream and downstream Oil & Gas applications where tight shut-off and low torque operation are essential. These valves provide reliable bi-directional sealing and are ideal for clean service fluids such as natural gas, refined fuels, and light hydrocarbons. Their design allows for low operating torque and reduced wear on the seats, making them suitable for high-cycle automated systems. Common installations include:

- Transmission Pipelines: Provide critical shut-off and isolation points along high-pressure natural gas or liquid hydrocarbon pipelines to ensure safe and efficient flow control over long distances.

- Metering Stations: Ensure tight shut-off around custody transfer points where accurate flow measurement and zero leakage are essential.

- Block Valve Stations: Act as sectional isolation points to enable maintenance, emergency shutdowns, or system segmentation without disrupting the entire pipeline network.

- Tank Farms: Control flow into and out of storage tanks, offering reliable sealing to prevent product loss and vapor emissions.

- Refineries: Regulate the flow of refined hydrocarbons and light products within process units, requiring bubble-tight sealing in clean fluid service.

- Compressor and Pump Stations: Manage the inlet and outlet flow of gas or liquids under pressure, maintaining integrity under high-cycle and automated operation.

Les vannes à boisseau sphérique à siège souple GVS API 6D sont largement utilisées dans les applications Oil & Gas midstream et downstream, là où l’étanchéité absolue et le faible couple de manœuvre sont essentiels. Elles offrent un double sens d’étanchéité fiable et conviennent parfaitement aux fluides propres comme le gaz naturel, les carburants raffinés et les hydrocarbures légers. Leur conception permet un fonctionnement à faible couple et réduit l’usure des sièges, ce qui les rend idéales pour les systèmes automatisés à cycles élevés. Exemples d’installations :

- Gazoducs de transport : Assurent l’isolement et la coupure sur les pipelines de gaz naturel ou d’hydrocarbures liquides à haute pression, pour un contrôle sûr et efficace sur de longues distances.

- Stations de comptage : Garantissent une fermeture étanche au niveau des points de transfert de propriété, où la précision de mesure et l’absence de fuite sont cruciales.

- Stations de sectionnement : Permettent l’isolement de sections pour la maintenance, les arrêts d’urgence ou la segmentation sans arrêter tout le réseau de conduites.

- Parcs de réservoirs : Contrôlent le flux vers et depuis les cuves de stockage, assurant une étanchéité fiable pour éviter toute perte de produit ou émission de vapeurs.

- Raffineries : Régulent le flux d’hydrocarbures raffinés et de produits légers dans les unités de process, nécessitant une étanchéité totale avec des fluides propres.

- Stations de compression et de pompage : Gèrent les flux d’entrée et de sortie de gaz ou liquides sous pression, tout en garantissant l’intégrité lors d’une exploitation automatisée à haut cycle.

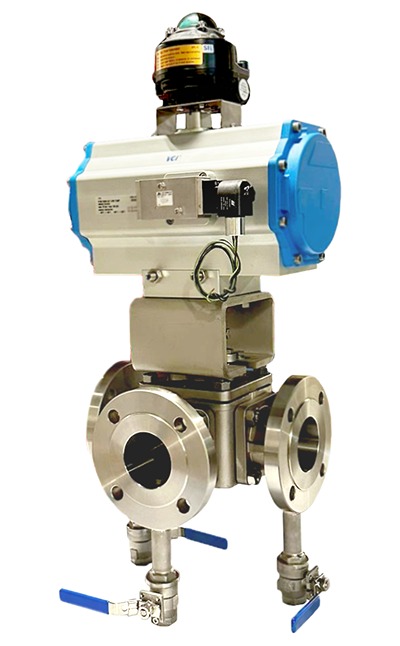

GVS Soft-Seated Trunnion Mounted Ball Valves are used in the petrochemical industry for tight shut-off and low-torque operation in clean service applications involving refined hydrocarbons, light chemicals, and process gases. These valves are commonly installed in processing units, storage terminals, loading systems, and chemical distribution networks, where reliable sealing and corrosion resistance are essential. Their design supports automated operation, extended cycle life, and minimal maintenance, making them ideal for batch processing, custody transfer, and flow isolation in complex petrochemical facilities.

- Processing Units: Provide low-torque, bubble-tight shut-off for refined hydrocarbons and clean chemical streams in reactors and separators.

- Storage Terminals: Ensure secure flow isolation and emission control at tank inlets and outlets for light chemicals and petrochemical products.

- Loading Systems: Deliver reliable sealing during the transfer of processed chemicals to railcars, tank trucks, or marine vessels.

- Chemical Distribution Networks: Manage flow direction and isolation across interconnected piping systems in downstream chemical plants.

- Custody Transfer Stations: Maintain accurate, leak-free shut-off to support precise metering and product accountability during transfers.

- Batch Processing Systems: Enable automated, repeatable shut-off in multi-step chemical production processes requiring clean service performance.

Les vannes à boisseau sphérique à siège souple GVS sont utilisées dans l’industrie pétrochimique pour une fermeture étanche et un faible couple de manœuvre sur des applications de fluides propres : hydrocarbures raffinés, produits chimiques légers, gaz de process. Elles sont couramment installées dans les unités de traitement, terminaux de stockage, systèmes de chargement et réseaux de distribution chimique, où l’étanchéité fiable et la résistance à la corrosion sont indispensables. Leur conception permet une automatisation aisée, une longue durée de vie en cycles et un entretien minimal, ce qui les rend idéales pour le traitement en batch, le transfert de propriété et l’isolement dans les usines complexes.

- Unités de traitement : Coupure étanche à faible couple pour les hydrocarbures raffinés et flux chimiques propres dans réacteurs et séparateurs.

- Terminaux de stockage : Isolement fiable et contrôle des émissions sur les entrées/sorties de cuves de produits pétrochimiques légers.

- Systèmes de chargement : Fermeture sûre lors du transfert de produits vers wagons, camions-citernes ou navires.

- Réseaux de distribution chimique : Gestion des directions de flux et isolement dans les réseaux interconnectés des usines chimiques aval.

- Stations de transfert de propriété : Coupure précise et sans fuite pour un comptage rigoureux lors des transferts.

- Systèmes de traitement par batch : Coupure automatique et répétable lors des processus chimiques en plusieurs étapes nécessitant un service propre.