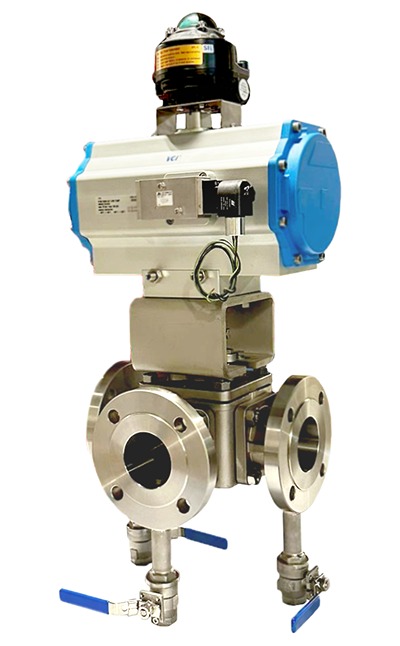

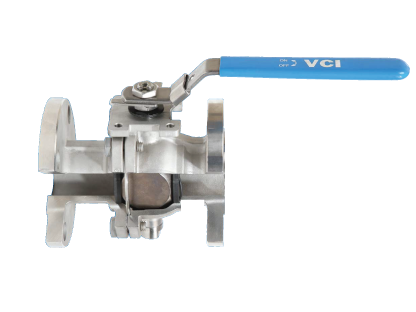

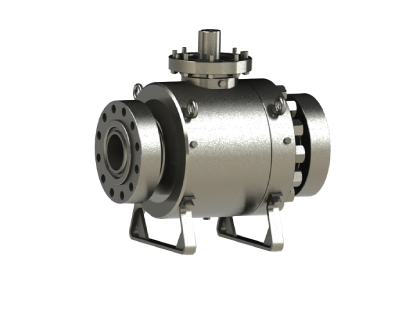

API 6A Ball Valves

Robinets à boisseau sphérique API 6A

GVS API 6A Ball Valves are manufactured in sizes 1 13/16” to 11” and for pressures of 2,000 to 10,000 PSI. These valves come standard with fire-safe certification and NACE, making them suitable for critical pressure control applications in the Oil & Gas industry.

Technical Specifications

Spécifications Techniques

- Design: API 6A

- Sizes: 1 13/16" – 11" Full & Reduced Port

- Pressures: 2,000 – 10,000 PSI

- Ends: RTJ, BW, and Hub

- Certifications: API 6A, API 6FA, NACE MR0175-SOUR

Features

Caractéristiques

- Bolted Body, 2-Piece & 3-Piece Construction

- Double Block and Bleed

- SPE and DPE Seat Design (SPE x SPE, DIB-1, DIB-2)

- Metal to Metal Seated and/or Soft Seated

- Anti-Blow-Out Stem Design

- Anti-Static Devices

- Bubble-Tight Shut-Off

- Fire Safe Certified: API 6FA

- NACE MR0175 SOUR