CSA/FM Approved Safety Shut-Off Valves for Petrochemical Applications

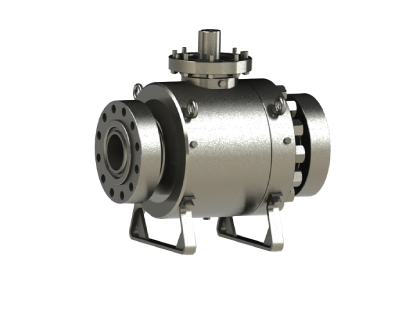

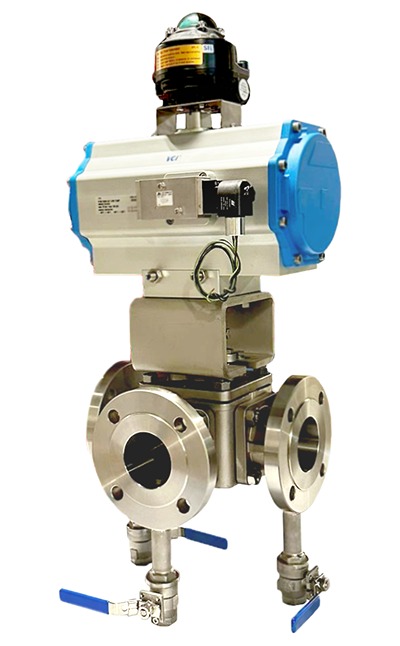

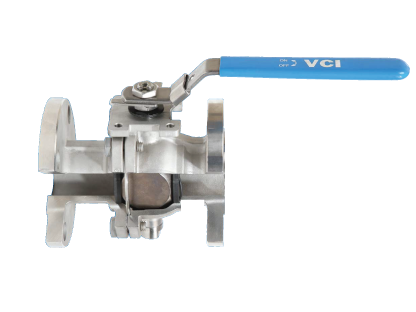

FM Approved Safety Shut-Off Ball Valves are used in the petrochemical industry to provide fire-safe, fail-safe isolation of flammable gases and liquids in systems where rapid emergency shutdown is critical to personnel safety and plant integrity. These valves are commonly installed in burner management systems, fuel gas trains, flare lines, chemical storage areas, process units, and loading/unloading stations, where they automatically shut off flow during abnormal conditions such as fire, pressure spikes, equipment failure, or system malfunction. FM Approval ensures compliance with stringent fire testing and performance standards, making these valves essential for process safety, hazard mitigation, and compliance with insurance and regulatory requirements in high-risk petrochemical operations.

-

Burner Management Systems:

Ensure automatic fuel shut-off to process heaters and furnaces during flame failure or unsafe operating conditions.

-

Fuel Gas Trains:

Provide certified isolation of flammable gas supplies to burners or reactors in compliance with fire safety standards.

-

Flare Lines:

Act as emergency isolation points to prevent uncontrolled flammable gas discharge during abnormal system operation or fire.

-

Chemical Storage Areas:

Isolate hazardous liquid or gas inventories in the event of fire or leak detection to prevent escalation of risk.

-

Process Units:

Serve as critical safety barriers that shut off fuel or feedstock during emergency shutdowns to protect equipment and personnel.

-

Loading and Unloading Stations:

Automatically shut off flow to tankers or railcars during fire, hose failure, or system malfunction.

Vannes de sécurité FM/CSA pour la pétrochimie

Les vannes à boisseau sphérique FM/CSA sont utilisées dans l'industrie pétrochimique pour assurer une isolation coupe-feu et sans faille des gaz et liquides inflammables, lorsque l'arrêt d'urgence est crucial pour la sécurité du personnel et l'intégrité des installations. Ces vannes sont généralement installées dans les systèmes de gestion des brûleurs, les trains de gaz, les lignes de torche, les zones de stockage chimique, les unités de procédé et les postes de chargement/déchargement, où elles arrêtent automatiquement le flux en cas d'incendie, de surpression, de défaillance d'équipement ou d'anomalie système. La certification FM/CSA garantit la conformité aux normes de test feu les plus strictes, ce qui rend ces vannes essentielles pour la sécurité des procédés, la réduction des risques et le respect des exigences réglementaires et assurantielles dans les opérations pétrochimiques à haut risque.

-

Systèmes de gestion des brûleurs :

Coupure automatique du carburant des fours et réchauffeurs lors de défaillance de flamme ou situation dangereuse.

-

Trains de gaz :

Isolation certifiée de l'alimentation en gaz vers brûleurs ou réacteurs selon les normes incendie.

-

Lignes de torche :

Points d'isolement d'urgence pour prévenir la fuite incontrôlée de gaz inflammable lors d'un incident ou incendie.

-

Zones de stockage chimique :

Isolement des stocks de liquides ou gaz dangereux en cas d'incendie ou de fuite détectée pour limiter les risques.

-

Unités de procédé :

Servent de barrières de sécurité critiques pour couper l'alimentation en carburant ou matière première lors d'un arrêt d'urgence.

-

Postes de chargement/déchargement :

Arrêt automatique du flux vers les camions-citernes ou wagons lors d'un incendie, d'une rupture de flexible ou d'une défaillance du système.

CSA/FM Approved Safety Shut-Off Ball Valves are used in the pulp and paper industry to provide fire-safe, fail-safe isolation of flammable gases and liquids in critical systems where combustion or heat processes are involved. These valves are commonly installed in boiler fuel gas lines, drying section burner trains, chemical processing areas, and emergency shutdown systems, where automatic shut-off is required to mitigate fire risks or prevent escalation during equipment failure. Their FM Approval ensures compliance with rigorous fire testing and safety standards, making them essential for burner

management, plant safety systems, and insurance compliance in hazardous pulp and paper operations.

- Boiler Fuel Gas Lines: Automatically isolate flammable gas supply to steam boilers in the event of flame failure or unsafe conditions.

- Drying Section Burner Trains: Provide certified, fire-safe shut-off to gas burners that heat paper drying cylinders or air systems.

- Chemical Processing Areas: Ensure rapid isolation of flammable solvents or gases used in pulping and bleaching processes during emergencies.

- Emergency Shutdown Systems: Act as critical safety barriers that shut off hazardous fluid or gas flows in the event of fire or system failure.

- Turbine or Engine Fuel Systems: Deliver fast, reliable shut-off to gas or liquid fuel supply lines for co-generation units in case of fault detection.

- Compliance with Insurance & Fire Codes: Fulfill FM Global and NFPA requirements for fire-safe valve installations in high-risk plant areas.

Les vannes de sécurité CSA/FM sont utilisées dans le papier/carton pour assurer une isolation coupe-feu et sans faille des gaz ou liquides inflammables dans les systèmes critiques liés à la chaleur ou à la combustion. On les trouve sur les lignes gaz chaudière, trains de brûleurs, zones process chimique et arrêts d’urgence, garantissant la coupure automatique en cas de défaillance pour prévenir l’incendie. La certification FM assure la conformité aux exigences feu et sécurité du site, ce qui les rend essentiels à la gestion des brûleurs, aux systèmes de sécurité des usines et à la conformité des assurances dans les opérations dangereuses de pâtes et papiers.

- Lignes gaz chaudière : Isolement automatique du gaz alimentant la chaudière vapeur en cas de défaut.

- Trains de brûleurs de séchage : Coupure certifiée pour brûleurs chauffant les cylindres ou systèmes d’air chaud.

- Zones process chimique : Isolement rapide des solvants/gaz inflammables utilisés en pâte ou blanchiment en urgence.

- Arrêt d’urgence : Barrière critique isolant fluides/gaz dangereux lors d’incendie ou défaillance process.

- Alim. carburant turbines/moteurs : Coupure rapide et fiable de l’alim gaz/liquide des groupes cogénération en cas de défaut.

- Conformité assurance/code feu : Conforme FM Global/NFPA pour les vannes coupe-feu sur sites à risque.

CSA/FM Approved Safety Shut-Off Ball Valves are used in the energy industry to ensure rapid, fire-safe isolation of fuel and process gases in critical systems where uncontrolled flow could lead to fire, explosion, or equipment damage. These valves are commonly installed in power plants, combined heat and power (CHP) systems, boiler gas lines, and turbine fuel supply systems, where they act as automated safety barriers during system faults or fire events. FM Approval guarantees compliance with strict safety standards, making these valves essential for burner management, emergency shutdown (ESD), and fail-safe automation in high-risk energy production environments.

- Power Plants: Provide certified emergency isolation of fuel gas lines to boilers or turbines in the event of fire or system failure.

- Combined Heat and Power (CHP) Systems: Ensure safe, automatic shut-off of fuel supply to integrated heat and power units during abnormal conditions.

- Boiler Gas Lines: Deliver fail-safe shut-off to prevent fuel flow to industrial burners during flame failure or overpressure events.

- Turbine Fuel Supply Systems: Act as critical safety devices that isolate combustible gas lines to turbines during emergency shutdowns.

- Burner Management Systems: Integrate into safety control systems to protect combustion processes with FM-certified fire-safe isolation.

- Emergency Shutdown (ESD) Circuits: Automatically isolate sections of the plant to mitigate hazards during fire, gas leak, or operational fault scenarios.

Les vannes CSA/FM approuvées sont utilisées dans l’énergie pour garantir une isolation coupe-feu rapide des gaz combustibles et de process dans les systèmes critiques où un flux incontrôlé pourrait provoquer incendie, explosion ou dégâts. Elles sont installées sur centrales électriques, unités cogénération, lignes gaz chaudière ou alimentation turbine, servant de barrière automatique lors de défauts ou incendie. La certification FM garantit conformité, sécurité et automatisation sur les sites énergétiques à haut risque.

- Centrales électriques : Isolation d’urgence certifiée des lignes gaz vers chaudières/turbines en cas d’incendie ou panne système.

- Unités chaleur/énergie combinée (CHP) : Coupure sécurisée du carburant pour les unités intégrées en conditions anormales.

- Lignes gaz chaudière : Arrêt de sécurité empêchant l’alimentation en gaz des brûleurs lors de défaut flamme ou surpression.

- Alimentation turbine : Isolement critique des lignes gaz vers turbines lors d’un arrêt d’urgence.

- Gestion des brûleurs : Intégration dans le système sécurité pour isolation coupe-feu certifiée FM des process combustion.

- Circuits arrêt d’urgence (ESD) : Isolement automatique de sections du site en cas d’incident, fuite gaz ou défaut process.

CSA/FM Safety Shut Off Valves for Food & Beverage

CSA/FM Approved Safety Shut-Off Valves are used in the food and beverage industry to provide fail-

safe, fire-safe isolation of fuel and gas lines that supply boilers, ovens, burners, and process heaters.

These valves are critical in bakeries, breweries, distilleries, spray drying plants, and dairy processing

facilities, where they automatically shut off the fuel supply during flame failure, overpressure, or fire to

protect personnel, equipment, and product integrity. Their CSA and FM certifications ensure compliance

with strict safety and insurance requirements, making them essential components in burner

management systems and emergency shutdown circuits throughout food and beverage production

plants.

- Bakeries: Automatically shut off the gas supply to ovens or proofing equipment during flame failure or system fault to prevent fire hazards.

- Breweries: Provide certified, fail-safe isolation of fuel gas lines to steam boilers or kettles in the event of unsafe operating conditions.

- Distilleries: Ensure rapid shutdown of burner fuel supply to stills or heating systems during emergency or fault detection.

- Spray Drying Plants: Stop fuel flow to spray dryer burners instantly if abnormal combustion conditions or flame loss occur.

- Dairy Processing Facilities: Isolate fuel supply to pasteurization boilers or process heaters to protect product quality and plant safety.

- Food Roasting Operations: Deliver fire-safe gas shut-off to roasting or drying ovens when abnormal conditions are detected.

Vannes de sécurité CSA/FM pour l’industrie alimentaire et des boissons

Les vannes d’arrêt de sécurité CSA/FM sont utilisées dans l’industrie alimentaire et des boissons pour assurer une isolation coupe-feu et sans faille des conduites de carburant et de gaz alimentant chaudières, fours, brûleurs et chauffe-process. Elles sont essentielles dans les boulangeries, brasseries, distilleries, usines de séchage par atomisation et installations de transformation laitière, où elles coupent automatiquement l’alimentation en carburant en cas de perte de flamme, de surpression ou d’incendie, afin de protéger le personnel, les équipements et l’intégrité des produits. Leur certification CSA et FM garantit la conformité aux exigences strictes de sécurité et d’assurance, ce qui en fait des composants indispensables dans les systèmes de gestion des brûleurs et les circuits d’arrêt d’urgence.

- Boulangeries : Coupure automatique de l’alimentation en gaz des fours ou chambres de pousse en cas de perte de flamme ou de défaut système.

- Brasseries : Isolation certifiée des conduites de gaz vers chaudières ou cuves en cas de conditions dangereuses.

- Distilleries : Arrêt rapide de l’alimentation en carburant des alambics ou systèmes de chauffe en cas d’urgence ou de défaut.

- Usines de séchage par atomisation : Arrêt instantané de l’alimentation des brûleurs en cas de combustion anormale ou perte de flamme.

- Installations laitières : Isolement du carburant pour protéger la qualité et la sécurité.

- Torréfaction alimentaire : Coupure coupe-feu des fours de torréfaction ou de séchage lors de conditions anormales.

CSA / FM Safety Shut Off Valves for Pharmaceutical Industry

CSA / FM Approved Safety Shut-Off Valves are used in the pharmaceutical industry to provide fail-safe,

fire-safe isolation in gas and fuel systems that support manufacturing, research, and facility operations.

These valves are commonly installed in boiler and steam generation fuel lines, laboratory burner

systems, and process heating equipment, where they automatically shut off the gas supply during

abnormal conditions such as flame failure, overpressure, or fire. Their CSA and FM certifications ensure

compliance with stringent safety codes, making them essential for protecting personnel, equipment,

and product integrity in pharmaceutical plants, pilot facilities, and R&D laboratories.

- Boiler and Steam Generation Fuel Lines: Automatically isolate natural gas or fuel supply to boilers when unsafe operating conditions are detected.

- Laboratory Burner Systems: Provide certified, fire-safe shut-off to lab burners during flame failure or emergency situations.

- Process Heating Equipment: Ensure rapid isolation of gas-fired heaters or ovens used in pharmaceutical manufacturing to prevent fire hazards.

- Pilot Plant Operations: Protect small-scale production systems by shutting off combustible gas flow in case of fault or detected flame loss.

- Emergency Shutdown Systems: Act as critical safety barriers that immediately halt fuel supply to any gas-fired process during a fire or system fault.

Vannes de sécurité CSA/FM pour l’industrie pharmaceutique

Les vannes d’arrêt de sécurité CSA/FM sont utilisées dans l’industrie pharmaceutique pour assurer une isolation coupe-feu et sans faille dans les systèmes de gaz et de carburant servant à la production, à la recherche et aux opérations du site. Elles sont installées dans les conduites d’alimentation en gaz des chaudières et générateurs de vapeur, les brûleurs de laboratoire et les équipements de chauffage de process, où elles coupent automatiquement le gaz en cas de perte de flamme, de surpression ou d’incendie. Leur certification CSA et FM garantit la conformité aux normes de sécurité les plus strictes, les rendant indispensables pour protéger le personnel, les équipements et l’intégrité des produits dans les usines, installations pilotes et laboratoires R&D.

- Conduites chaudières/vapeur : Isolement automatique du gaz ou carburant des chaudières en cas de conditions dangereuses.

- Systèmes de brûleurs de laboratoire : Coupure coupe-feu certifiée des brûleurs en cas de perte de flamme ou d’urgence.

- Équipements de chauffage de process : Isolement rapide des fours ou chauffages au gaz pour éviter les incendies.

- Installations pilotes : Protection des systèmes à petite échelle par coupure du gaz en cas de défaut ou de perte de flamme.

- Systèmes d’arrêt d’urgence : Coupure immédiate de l’alimentation en carburant lors d’un incendie ou d’un défaut système.