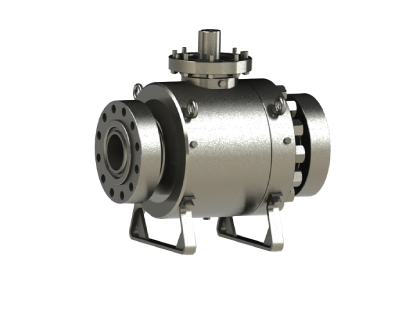

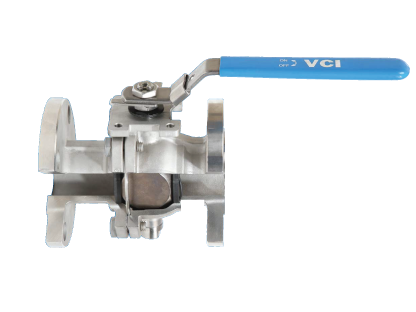

GVS Severe Service Trunnion-Mounted Ball Valves are used in the most demanding Oil & Gas applications where extreme pressures, temperatures, and fluid conditions exceed the capabilities of standard valve designs. These valves are critical in high-pressure gas transmission, abrasive slurry handling, and emergency shut-down systems where reliability and zero leakage are essential for safety and performance. Engineered with enhanced materials, specialized coatings, and metal-to-metal or engineered seat designs, they ensure long-term sealing integrity under corrosive, erosive, or cyclic loading conditions.

- High-Pressure Gas Transmission: Provide reliable isolation in long-distance gas pipelines operating at elevated pressures and requiring zero leakage and high cycle life.

- Abrasive Slurry Handling: Manage erosive mixtures of sand, scale, and hydrocarbons in upstream production or oil sands, where standard valves would rapidly degrade.

- Emergency Shutdown Systems: Ensure fast, fail-safe closure in critical isolation scenarios, often integrated with high-integrity pressure protection systems (HIPPS).

Les vannes à boisseau sphérique “Severe Service” GVS, montées sur tourillon, sont utilisées dans les applications Oil & Gas les plus extrêmes où la pression, la température et les conditions de fluide dépassent les limites des conceptions standard. Ces vannes sont essentielles pour le transport de gaz haute pression, la gestion de boues abrasives et les systèmes d’arrêt d’urgence, où la fiabilité et l’étanchéité absolue sont vitales pour la sécurité et la performance. Grâce à des matériaux avancés, des revêtements spéciaux et des sièges métalliques ou techniques, elles garantissent une étanchéité durable même en conditions corrosives, érosives ou cycliques.

- Transport de gaz haute pression : Isolation fiable dans les gazoducs longue distance à pression élevée nécessitant zéro fuite et une longue durée de vie en cycles.

- Gestion de boues abrasives : Traite les mélanges érosifs de sable, tartre et hydrocarbures en production amont ou sables bitumineux, là où les vannes standard s’usent rapidement.

- Systèmes d’arrêt d’urgence : Fermeture rapide et sécurisée dans les scénarios critiques, souvent intégrée à des systèmes HIPPS de protection pression haute intégrité.

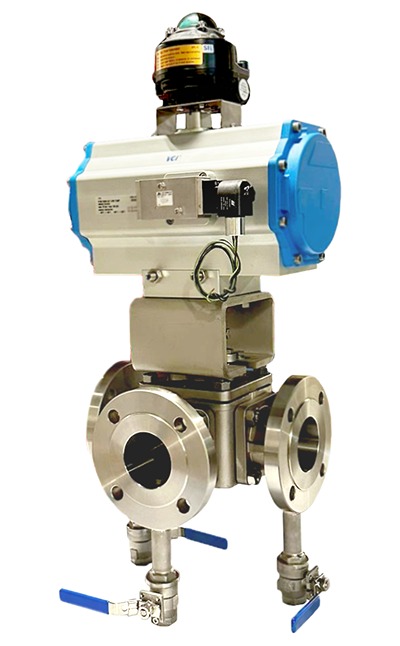

GVS Severe Service Trunnion Mounted Ball Valves are used in the petrochemical industry for critical isolation and flow control in the most demanding operating conditions, including high-pressure, high-temperature, and aggressive chemical environments. These valves are commonly found in hydrogen reforming units, polymer production lines, acid handling systems, and high-cycle automated processes, where standard valves would fail due to erosion, corrosion, or thermal fatigue. Engineered with specialized coatings, metal-to-metal seating, and robust materials, they ensure long-term sealing integrity, safety, and operational reliability in mission-critical petrochemical applications.

- Hydrogen Reforming Units: Deliver high-integrity shut-off under extreme pressures and temperatures in hydrogen-rich, corrosive environments.

- Polymer Production Lines: Handle high-viscosity, abrasive, or chemically reactive media where standard valve components would quickly degrade.

- Acid Handling Systems: Provide corrosion-resistant isolation in lines carrying aggressive acids such as sulfuric or hydrochloric acid.

- High-Cycle Automated Processes: Withstand frequent actuation and thermal cycling in continuous or batch operations requiring tight, repeatable sealing.

- Dehydration and Amine Units: Maintain leak-tight performance in systems exposed to amine degradation and high-temperature regeneration cycles.

- Critical Safety Isolation Points: Serve as last-line barriers in high-risk applications where failure could result in hazardous release or process disruption.

Les vannes à boisseau sphérique “Severe Service” GVS sont utilisées dans la pétrochimie pour l’isolement et le contrôle du débit dans les conditions les plus sévères : haute pression, température extrême et milieux chimiques agressifs. On les trouve dans les unités de reformage hydrogène, lignes de production de polymères, circuits d’acides et process automatisés à cycles élevés, où l’érosion, la corrosion ou la fatigue thermique détruisent les vannes classiques. Avec leurs revêtements spécialisés, sièges métal-métal et matériaux robustes, elles assurent une étanchéité, une sécurité et une fiabilité opérationnelle maximales dans les applications critiques.

- Unités de reformage hydrogène : Coupure haute intégrité sous pressions et températures extrêmes dans des milieux hydrogénés et corrosifs.

- Lignes de production de polymères : Supportent les fluides très visqueux, abrasifs ou réactifs qui dégraderaient des vannes classiques.

- Systèmes de manipulation d’acides : Isolement résistant à la corrosion pour les lignes transportant des acides agressifs comme l’acide sulfurique ou chlorhydrique.

- Process automatisés à cycles élevés : Résistent à de fréquentes manœuvres et aux cycles thermiques en continu ou par batch, tout en gardant une étanchéité parfaite.

- Unités de déshydratation et amines : Maintien d’une performance étanche sur des systèmes exposés à la dégradation des amines et aux régénérations haute température.

- Points d’isolement de sécurité critiques : Barrière de dernière ligne dans les applications à haut risque, où toute défaillance causerait une fuite dangereuse ou une interruption majeure de process.