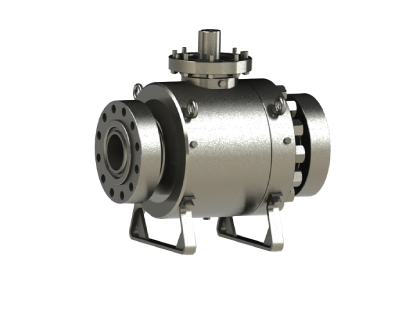

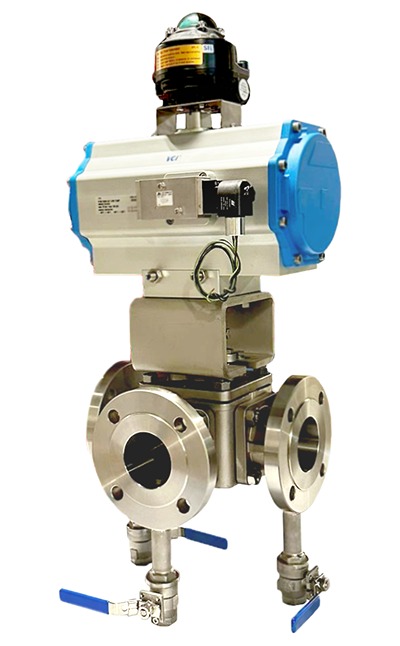

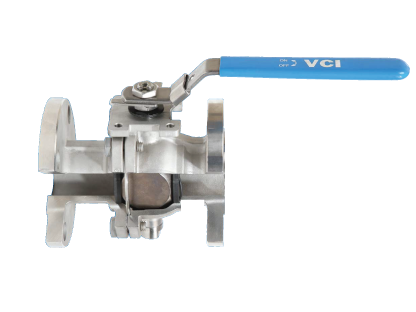

GVS Pressure-Balanced, Lubricated Plug Valves are used in the petrochemical industry for reliable isolation and flow control in applications involving viscous, abrasive, or corrosive fluids where bubble-tight sealing and in-line maintainability are critical. These valves are commonly installed in gas processing units, chemical transfer lines, storage terminals, and high-pressure manifold systems, where they handle hydrocarbons, solvents, and process gases with minimal leakage and wear. Their pressure-balanced design ensures smooth operation under high differential pressures, while the ability to inject sealant allows for restored sealing performance without shutdown, making them ideal for demanding, high-cycle service in petrochemical facilities.

- Gas Processing Units: Provide tight shut-off and smooth operation for isolating and redirecting process gases under high pressure.

- Chemical Transfer Lines: Handle viscous or corrosive fluids with reliable sealing and in-line lubrication to extend service life.

- Storage Terminals: Control the flow of petrochemicals in and out of tanks, ensuring safe, leak-tight isolation in bulk handling operations.

- High-Pressure Manifold Systems: Enable flexible flow routing with balanced pressure control in complex piping arrangements.

- Solvent Handling Systems: Resist chemical attack while providing bubble-tight shut-off in lines carrying aggressive solvents and light hydrocarbons.

- Process Isolation Points: Allow for dependable in-line maintenance and resealing, minimizing downtime during routine service in critical units.

Les vannes à clapet lubrifié, équilibrées en pression GVS, sont utilisées dans l’industrie pétrochimique pour l’isolement fiable et le contrôle du débit des fluides visqueux, abrasifs ou corrosifs, là où l’étanchéité absolue et la maintenance en ligne sont critiques. Elles sont couramment installées dans les unités de traitement de gaz, les lignes de transfert de produits chimiques, les terminaux de stockage et les collecteurs haute pression. Elles gèrent les hydrocarbures, solvants et gaz de process avec un minimum de fuite et d’usure. Leur conception équilibrée assure un fonctionnement souple sous forte pression différentielle, tandis que l’injection de lubrifiant permet de restaurer l’étanchéité sans arrêt de production, idéal pour les services exigeants à haut cycle.

- Unités de traitement de gaz : Coupure étanche et fonctionnement régulier pour l’isolement et la dérivation de gaz sous haute pression.

- Lignes de transfert chimiques : Manipulation de fluides visqueux ou corrosifs avec étanchéité fiable et lubrification en ligne pour prolonger la durée de vie.

- Terminaux de stockage : Contrôle du flux de pétrochimiques à l’entrée/sortie des cuves, pour une isolation sûre et sans fuite lors des opérations de vrac.

- Collecteurs haute pression : Permet la dérivation flexible des flux avec gestion équilibrée de la pression dans les réseaux complexes.

- Systèmes de manipulation de solvants : Résistent à l’attaque chimique tout en assurant une coupure étanche dans les lignes transportant solvants agressifs et hydrocarbures légers.

- Points d’isolement process : Permettent maintenance et re-lubrification en ligne, limitant les arrêts lors de l’entretien dans les unités critiques.

GVS Pressure-Balanced, Lubricated Plug Valves are used in Oil & Gas applications where tight shut-off, durability, and resistance to abrasive or viscous media are required. These valves are commonly installed in natural gas gathering systems, crude oil and multiphase pipelines, manifolds, metering stations, and terminal facilities. Their pressure-balanced design ensures smooth operation under high differential pressures, while the injection of sealing compound enhances sealing performance and allows for in-line maintenance—making them ideal for both upstream and midstream service in harsh environments.

- Natural Gas Gathering Systems: Provide reliable shut-off and pressure control in field gas collection lines, even with wet or dirty gas.

- Crude Oil and Multiphase Pipelines: Handle viscous fluids, waxy crude, and gas-liquid mixtures with minimal pressure drop and strong sealing integrity.

- Manifolds: Enable flexible flow routing and isolation in high-pressure manifold assemblies at well sites or central processing facilities.

- Metering Stations: Maintain bubble-tight sealing for accurate flow measurement and custody transfer in gas or liquid service.

- Terminal Facilities: Control the loading and unloading of hydrocarbons in tank farms and export terminals, offering durability and in-line maintainability.

Les vannes à clapet lubrifié, équilibrées en pression GVS sont utilisées dans l’Oil & Gas pour garantir une coupure étanche, une grande durabilité et une résistance aux fluides abrasifs ou visqueux. On les trouve dans les réseaux de collecte de gaz naturel, les pipelines de brut et multiphase, les collecteurs, stations de comptage et terminaux. Leur conception équilibrée permet un fonctionnement souple sous forte pression différentielle, tandis que l’injection de lubrifiant optimise l’étanchéité et autorise la maintenance en ligne, idéale en amont et au milieu de chaîne dans les environnements sévères.

- Réseaux de collecte de gaz naturel : Coupure fiable et contrôle de pression dans les lignes de collecte, même avec des gaz humides ou sales.

- Pipelines de brut et multiphase : Gèrent les fluides visqueux, bruts paraffiniques et mélanges gaz-liquide avec faible perte de charge et excellente étanchéité.

- Collecteurs : Dérivation flexible et isolement dans les collecteurs haute pression sur site ou en centre de traitement.

- Stations de comptage : Assurent l’étanchéité pour une mesure de débit précise et les transferts de propriété en service gaz ou liquide.

- Terminaux : Contrôle du chargement/déchargement d’hydrocarbures dans les parcs à réservoirs et terminaux d’export, avec durabilité et maintenance en ligne.