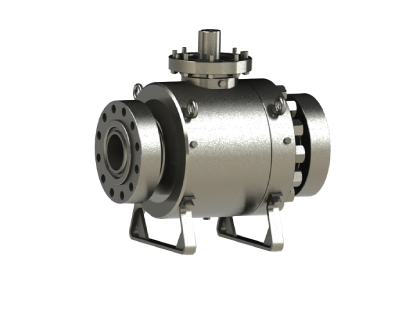

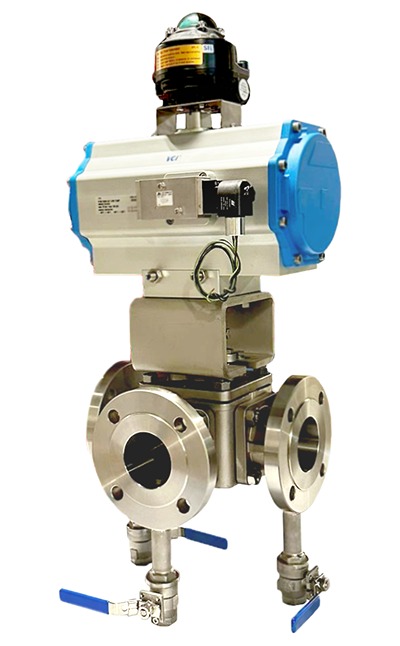

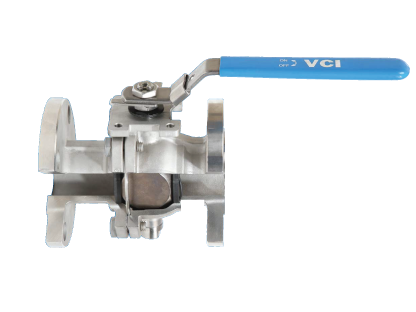

GVS Cryogenic Floating Ball Valves are used in the energy industry for compact, low-temperature flow control of liquefied gases such as LNG, LPG, and liquid nitrogen, particularly in small to mid-size pipeline systems. These valves are ideal for applications such as LNG vaporizer skids, satellite regasification units, cryogenic fueling stations, and portable energy modules, where reliable sealing and thermal resilience are essential. Their floating ball design, extended bonnets, and cryogenic-compatible materials make them well-suited for installations requiring tight shut-off, space efficiency, and automated operation under extreme cold conditions.

- LNG Vaporizer Skids: Provide compact, cryogenic shut-off and control during the transition of LNG from liquid to gas phase.

- Satellite Regasification Units: Ensure safe and reliable flow isolation in modular LNG regasification systems for remote or off-grid energy supply.

- Cryogenic Fueling Stations: Control the dispensing of LNG or liquid hydrogen in vehicle or industrial fueling operations, ensuring leak-tight performance.

- Portable Energy Modules: Offer lightweight, space-efficient cryogenic flow control in mobile power generation or backup systems.

- Small-Bore Cryogenic Pipelines: Deliver precise, low-torque shut-off for liquefied gases in confined or short-distance distribution networks.

- LNG Distribution Trailers: Enable safe loading and unloading operations of LNG in transport trailers under extreme cold and pressure conditions.

Les vannes cryogéniques à boisseau sphérique flottant GVS sont utilisées dans l’industrie de l’énergie pour le contrôle compact et basse température des gaz liquéfiés (GNL, GPL, azote liquide), en particulier sur les réseaux petits et moyens diamètres. Idéales pour les modules de vaporisation GNL, unités satellites de regazéification, stations de ravitaillement cryogénique et modules d’énergie portables, elles allient étanchéité fiable et résistance thermique. Leur conception flottante, bonnet rallongé et matériaux compatibles cryogénie les rendent parfaites pour les installations à fermeture étanche, compacité et automatisation sous froid extrême.

- Modules de vaporisation GNL : Coupure cryogénique compacte lors de la transition du GNL de l’état liquide à gazeux.

- Unités satellites de regazéification : Isolement sûr et fiable dans les modules LNG pour alimentation déportée ou hors réseau.

- Stations de ravitaillement cryogénique : Contrôle du remplissage LNG ou hydrogène liquide pour véhicules ou industries, avec étanchéité parfaite.

- Modules d’énergie portables : Régulation cryogénique légère et compacte pour générateurs ou secours mobiles.

- Réseaux cryogéniques petits diamètres : Coupure précise, faible couple, sur les réseaux confinés ou courtes distances de gaz liquéfiés.

- Remorques de distribution GNL : Chargement et déchargement sûrs du LNG en transport routier sous froid et pression extrêmes.

GVS Floating Cryogenic Ball Valves are used in Oil & Gas applications where compact design and reliable sealing are required for handling low-temperature liquefied gases, such as LNG, LPG, and liquid nitrogen, in smaller-diameter piping systems. These valves are ideal for LNG vaporizer skids, distribution trailers, portable fueling systems, and cryogenic transfer lines, where space is limited and precise flow control is essential. Their floating ball design ensures tight shut-off at cryogenic temperatures, while extended bonnets protect stem seals from thermal shock and maintain operational integrity.

- LNG Vaporizer Skids: Provide reliable isolation and flow control for LNG as it transitions from liquid to gas during the vaporization process.

- Cryogenic Distribution Trailers: Ensure safe shut-off and control of liquefied gases during transport and offloading operations.

- Portable Fueling Systems: Control the flow of LNG or liquid hydrogen in mobile refueling units for industrial or vehicular use.

- Cryogenic Transfer Lines: Maintain tight sealing and temperature resilience in small-bore piping systems transferring liquefied gases between vessels.

- LNG Satellite Stations: Manage inlet and outlet flow in modular LNG regasification or storage units supplying remote energy demands.

Les vannes cryogéniques flottantes GVS sont utilisées dans l’Oil & Gas pour la gestion des gaz liquéfiés à basse température (GNL, GPL, azote liquide) sur tuyauteries petit diamètre, là où la compacité et l’étanchéité sont prioritaires. Idéales pour modules de vaporisation LNG, remorques de distribution, systèmes de ravitaillement portables et lignes de transfert cryogéniques, elles garantissent le contrôle précis même en espace limité. Le design flottant assure la fermeture étanche sous froid extrême, tandis que le bonnet rallongé protège l’étanchéité de tige contre le choc thermique.

- Modules de vaporisation LNG : Isolement fiable et contrôle du flux lors du passage LNG liquide à gaz.

- Remorques de distribution cryogénique : Coupure et contrôle sécurisés lors du transport et déchargement des gaz liquéfiés.

- Systèmes de ravitaillement portables : Contrôle du LNG ou hydrogène liquide sur unités mobiles pour véhicules ou industries.

- Lignes de transfert cryogénique : Étanchéité et résistance thermique sur les petits réseaux transférant des gaz liquéfiés d’un réservoir à l’autre.

- Stations satellites LNG : Gestion entrée/sortie dans les modules de regazéification ou stockage pour alimenter des sites isolés.

GVS Floating Cryogenic Ball Valves for Food & Beverage

GVS Floating Cryogenic Ball Valves are used in the food and beverage industry for reliable, low-

temperature flow control of liquefied gases such as liquid nitrogen (LN₂) and carbon dioxide (CO₂) in

processing, packaging, and preservation applications. They are commonly installed in cryogenic freezing

tunnels, liquid nitrogen dosing systems, carbonation lines, and cold storage facilities, where precise

shut-off and thermal resilience are essential. Their floating ball design, extended bonnets, and

cryogenic-compatible materials ensure bubble-tight sealing, minimal heat transfer to the stem, and long

service life in high-purity, hygienic environments.

- Cryogenic Freezing Tunnels: Provide reliable shut-off and flow control of liquid nitrogen for rapid freezing of food products.

- Liquid Nitrogen Dosing Systems: Control LN₂ injection into beverage containers for pressurization and extended shelf life.

- Carbonation Lines: Ensure precise isolation of liquid CO₂ during beverage carbonation processes.

- Cold Storage Facilities: Regulate cryogenic gas supply to maintain ultra-low temperatures for bulk food preservation.

- Modified Atmosphere Packaging (MAP) Lines: Control cryogenic gas flow during inert atmosphere creation for packaged foods.

- Cryogenic Grinding Systems: Manage liquid nitrogen delivery to mills for processing heat-sensitive food ingredients.

Vannes cryogéniques flottantes GVS pour l’industrie alimentaire et des boissons

Les vannes cryogéniques flottantes GVS sont utilisées dans l’industrie alimentaire et des boissons pour le contrôle fiable à basse température des gaz liquéfiés tels que l’azote liquide (LN₂) et le dioxyde de carbone (CO₂) dans les applications de transformation, conditionnement et conservation. Elles sont couramment installées dans les tunnels de congélation cryogénique, les systèmes de dosage d’azote liquide, les lignes de carbonatation et les installations de stockage à froid, où une fermeture précise et une résistance thermique sont essentielles. Leur conception à boisseau sphérique flottant, leurs bonnet rallongés et leurs matériaux compatibles cryogénie garantissent une étanchéité parfaite, un transfert thermique minimal vers la tige et une longue durée de vie dans des environnements hygiéniques de haute pureté.

- Tunnels de congélation cryogénique : Coupure fiable et contrôle du flux d’azote liquide pour congélation rapide des produits alimentaires.

- Systèmes de dosage d’azote liquide : Contrôle de l’injection de LN₂ dans les contenants de boissons pour pressurisation et allongement de la durée de conservation.

- Lignes de carbonatation : Isolation précise du CO₂ liquide pendant les procédés de carbonatation des boissons.

- Installations de stockage à froid : Régulation de l’alimentation en gaz cryogénique pour maintenir des températures ultra-basses pour la conservation alimentaire en vrac.

- Lignes d’emballage sous atmosphère modifiée (MAP) : Contrôle du flux de gaz cryogénique pour la création d’atmosphères inertes dans les emballages.

- Systèmes de broyage cryogénique : Gestion de l’alimentation en azote liquide pour le broyage d’ingrédients alimentaires sensibles à la chaleur.