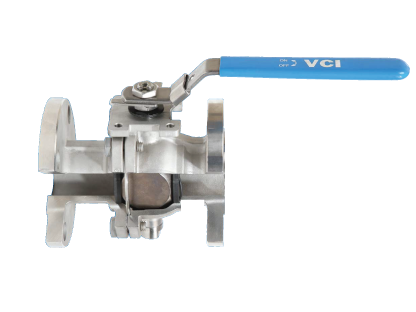

The Series 11F Instrument Isolation Valve is used in the food and beverage industry to provide compact,

sanitary isolation for gauges, sensors, transmitters, and sampling devices without disrupting production.

Its wafer-style design minimizes dead space, making it suitable for fermentation tanks, pasteurization

systems, brewery and distillery process lines, and CIP/SIP loops, where cleanliness and hygiene are

paramount. By allowing instruments to be safely removed, calibrated, or replaced while maintaining

process integrity, the 11F valve supports continuous, contamination-free operation in high-purity food

and beverage environments.

La vanne d’isolement d’instrument Série 11F est utilisée dans l’industrie agroalimentaire pour offrir une isolation

compacte et sanitaire des manomètres, capteurs, transmetteurs et dispositifs d’échantillonnage sans interrompre la production.

Son design wafer réduit les volumes morts, ce qui la rend adaptée aux cuves de fermentation, aux systèmes de pasteurisation,

aux lignes de process des brasseries et distilleries, ainsi qu’aux boucles CIP/SIP, où propreté et hygiène sont essentielles.

En permettant de retirer, d’étalonner ou de remplacer les instruments en toute sécurité tout en préservant l’intégrité du process,

la 11F assure un fonctionnement continu et sans contamination dans des environnements agroalimentaires à haute pureté.

-

Fermentation Tanks:

Allow safe isolation and removal of pressure or temperature sensors without interrupting fermentation.

Cuves de fermentation :

Permettent l’isolement et le retrait en toute sécurité des capteurs de pression ou de température sans interrompre la fermentation.

-

Pasteurization Systems:

Enable quick servicing of instrumentation while maintaining sanitary conditions in heat treatment lines.

Systèmes de pasteurisation :

Permettent une maintenance rapide des instruments tout en conservant des conditions sanitaires sur les lignes de traitement thermique.

-

Brewery and Distillery Process Lines:

Provide clean, compact shut-off for gauges and meters in wort, mash, or distillation circuits.

Lignes de process brasseries & distilleries :

Assurent une fermeture propre et compacte pour les manomètres et débitmètres dans le moût, l’empâtage ou les circuits de distillation.

-

CIP/SIP Loops:

Isolate monitoring devices during cleaning or sterilization to protect sensitive instruments.

Boucles CIP/SIP :

Isolent les dispositifs de surveillance pendant le nettoyage ou la stérilisation afin de protéger les instruments sensibles.

-

Beverage Filling Lines:

Facilitate maintenance of flow meters or pressure transmitters without halting packaging operations.

Lignes de remplissage de boissons :

Facilitent la maintenance des débitmètres ou transmetteurs de pression sans arrêter les opérations de conditionnement.

-

Dairy Processing Equipment:

Permit hygienic isolation of sensors in milk, cream, or yogurt processing lines to ensure compliance with food safety standards.

Équipements de transformation laitière :

Permettent l’isolement hygiénique des capteurs sur les lignes de lait, crème ou yaourt pour garantir la conformité aux normes de sécurité alimentaire.

The Series 11F Instrument Isolation Valve is used in the pharmaceutical industry to provide compact,

sanitary isolation of process instrumentation such as pressure gauges, transmitters, flow meters, and

sampling devices. It is commonly applied in bioreactors, fermentation vessels, purified water systems,

and CIP/SIP loops, allowing instruments to be removed, calibrated, or serviced without interrupting

sterile production. Its wafer-style design and clean flow path make it ideal for high-purity applications,

helping maintain product integrity while minimizing dead space and contamination risk.

La vanne d’isolement d’instrument Série 11F est utilisée dans l’industrie pharmaceutique pour assurer une isolation

compacte et sanitaire des instruments de process tels que manomètres, transmetteurs, débitmètres et dispositifs d’échantillonnage.

Elle est couramment appliquée sur les bioréacteurs, les cuves de fermentation, les systèmes d’eau purifiée et les boucles CIP/SIP,

permettant de retirer, d’étalonner ou de maintenir les instruments sans interrompre la production stérile.

Son design wafer et son chemin d’écoulement propre la rendent idéale pour les applications de haute pureté, aidant à maintenir

l’intégrité du produit tout en minimisant les volumes morts et le risque de contamination.

-

Bioreactors:

Allow safe isolation and removal of sensors or gauges for calibration without disturbing sterile fermentation conditions.

Bioréacteurs :

Permettent l’isolement et le retrait en toute sécurité des capteurs ou manomètres pour l’étalonnage sans perturber les conditions stériles de fermentation.

-

Fermentation Vessels:

Provide sanitary shut-off for instrumentation during maintenance while preserving batch integrity.

Cuves de fermentation :

Assurent une fermeture sanitaire des instruments pendant la maintenance tout en préservant l’intégrité du lot.

-

Purified Water Systems:

Enable calibration or replacement of flow and pressure instruments without contaminating high-purity water loops.

Systèmes d’eau purifiée :

Permettent l’étalonnage ou le remplacement des instruments de débit et de pression sans contaminer les boucles d’eau de haute pureté.

-

CIP/SIP Loops:

Isolate monitoring devices during cleaning or sterilization cycles to protect sensitive components.

Boucles CIP/SIP :

Isolent les dispositifs de surveillance pendant les cycles de nettoyage ou de stérilisation pour protéger les composants sensibles.

-

Filling and Packaging Lines:

Allow quick service of instrumentation in aseptic filling systems without halting production.

Lignes de remplissage et conditionnement :

Permettent une intervention rapide sur les instruments des systèmes de remplissage aseptique sans arrêter la production.

-

R&D Pilot Systems:

Facilitate frequent instrument changes and testing in small-scale pharmaceutical development setups.

Systèmes pilotes R&D :

Facilitent les changements fréquents d’instruments et les essais dans des dispositifs de développement pharmaceutique à petite échelle.

GVS 11F Instrument Isolation Valves are used in the automotive industry to provide compact, reliable

shut-off for instruments, gauges, and sensors during maintenance, calibration, or testing. Their

lightweight, wafer-style design makes them ideal for engine and powertrain test rigs, fuel system

monitoring stations, emissions measurement equipment, and hydraulic or pneumatic test benches,

where space is limited, and frequent instrument isolation is required. These valves help ensure accurate

readings, protect sensitive measurement devices, and allow for quick removal or replacement without

disrupting the entire system.

Les vannes d’isolement d’instrument GVS 11F sont utilisées dans l’industrie automobile pour fournir un isolement

compact et fiable des instruments, manomètres et capteurs lors des opérations de maintenance, d’étalonnage ou d’essais.

Leur conception wafer légère les rend idéales pour les bancs d’essai moteurs et groupes motopropulseurs, les stations de

surveillance des systèmes de carburant, les équipements de mesure des émissions, ainsi que les bancs d’essais

hydrauliques ou pneumatiques, où l’espace est limité et où l’isolement fréquent des instruments est requis.

Ces vannes contribuent à garantir des mesures précises, à protéger les dispositifs sensibles et à permettre un retrait

ou un remplacement rapide sans perturber l’ensemble du système.

-

Engine and Powertrain Test Rigs:

Allow precise isolation of measurement devices during engine or drivetrain performance testing without system depressurization.

Bancs d’essai moteurs & groupes motopropulseurs :

Permettent l’isolement précis des dispositifs de mesure lors des essais de performance sans dépressuriser le système.

-

Fuel System Monitoring Stations:

Provide safe shut-off for pressure and flow sensors in fuel delivery systems during calibration or maintenance.

Stations de surveillance des systèmes de carburant :

Assurent une fermeture sûre pour les capteurs de pression et de débit des circuits d’alimentation lors de l’étalonnage ou de la maintenance.

-

Emissions Measurement Equipment:

Enable quick isolation of gas analyzers and sampling devices to protect against contamination or damage.

Équipements de mesure des émissions :

Permettent l’isolement rapide des analyseurs de gaz et dispositifs d’échantillonnage pour éviter la contamination ou les dommages.

-

Hydraulic Test Benches:

Isolate gauges and transducers in high-pressure hydraulic circuits to prevent overloading during system adjustments.

Bancs d’essai hydrauliques :

Isolent manomètres et transducteurs dans les circuits hydrauliques haute pression pour éviter les surcharges lors des réglages.

-

Pneumatic Test Benches:

Control air supply to instrumentation for brake, suspension, or component testing while allowing safe service access.

Bancs d’essai pneumatiques :

Contrôlent l’alimentation en air des instruments pour les tests de freinage, suspension ou composants tout en permettant un accès sécurisé.

-

Cooling System Test Stands:

Facilitate the removal and calibration of temperature or pressure sensors in coolant flow lines without interrupting testing.

Bancs d’essai des systèmes de refroidissement :

Facilitent le retrait et l’étalonnage des capteurs de température ou de pression sur les circuits de liquide de refroidissement sans interrompre les tests.