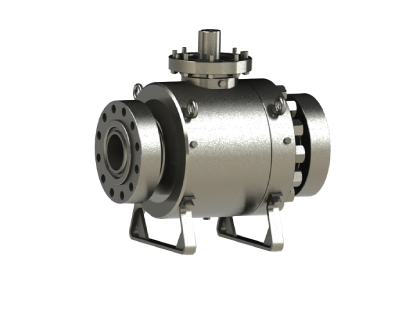

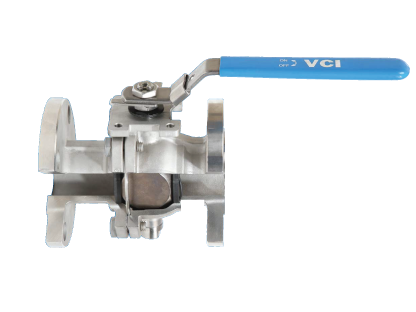

GVS LOWE Valves are used in the pulp and paper industry for compact, high-performance flow control in applications involving abrasive slurries, chemical additives, and steam or condensate lines. Their metal-to-metal seated, quarter-turn design provides durable, bubble-tight shut-off in harsh conditions, making them ideal for digester inlets, chemical recovery loops, and utility systems where conventional soft-seated valves may wear out quickly. The LOWE valve’s low-torque operation and erosion-resistant construction make it particularly suitable for high-cycle, space-constrained installations throughout pulp and paper processing lines.

- Digester Inlets: Provide durable, metal-seated shut-off for abrasive pulp slurries entering continuous or batch digesters.

- Chemical Recovery Loops: Ensure long-lasting isolation in corrosive and high-temperature environments typical of black liquor and chemical recovery systems.

- Steam and Condensate Lines: Offer tight shut-off and thermal cycling resistance in utility systems supporting drying and heating processes.

- Additive Injection Systems: Deliver precise control of process chemicals and retention aids with reliable sealing in high-cycle applications.

- Wash Water and Dilution Lines: Handle water-based media with entrained solids while maintaining bubble-tight performance and minimal wear.

- Stock Transfer Lines: Manage the flow of semi-finished pulp between processing stages where space constraints demand a compact, robust valve solution.

Les vannes GVS LOWE sont utilisées dans l’industrie du papier et de la pâte à papier pour un contrôle de débit compact et performant, notamment avec des boues abrasives, des additifs chimiques, et sur les lignes de vapeur ou de condensat. Leur conception quart de tour à siège métal-métal offre une étanchéité parfaite et durable dans les conditions difficiles, ce qui les rend idéales pour les admissions de digesteur, les boucles de récupération chimique et les utilités où les vannes à siège souple s’usent rapidement. Leur faible couple de manœuvre et leur résistance à l’érosion sont parfaits pour les installations à espace réduit et à cycles élevés tout au long des lignes de transformation.

- Admissions de digesteur : Coupure durable et siège métallique pour les boues de pâte abrasives en entrée de digesteurs continus ou batch.

- Boucles de récupération chimique : Isolation durable en environnement corrosif et haute température, typique des systèmes de liqueur noire et de récupération.

- Lignes de vapeur et condensat : Fermeture étanche et résistance au cyclage thermique sur les utilités liées au séchage et chauffage.

- Systèmes d’injection d’additifs : Contrôle précis des produits chimiques et agents de rétention avec étanchéité fiable pour applications à cycles élevés.

- Lignes d’eau de lavage et dilution : Gère les fluides chargés de solides tout en conservant une étanchéité parfaite et une usure minimale.

- Lignes de transfert de pâte : Gestion du transfert de la pâte semi-finie entre les étapes, idéale pour les espaces exigus nécessitant une vanne compacte et robuste.

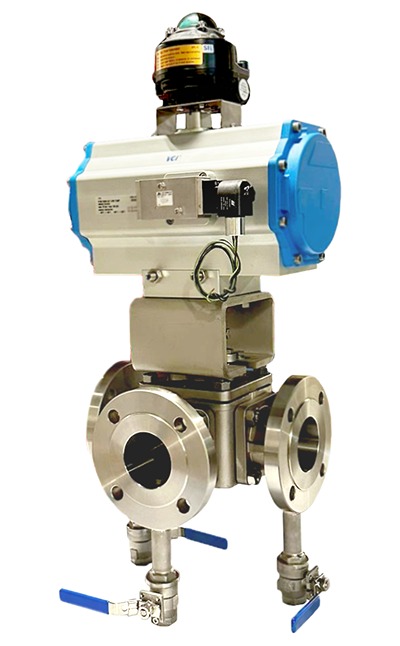

The GVS LOWE valve, featuring a compact, metal-to-metal seated quarter-turn design, is used in the petrochemical industry for precise flow control and reliable shut-off in applications involving abrasive, corrosive, or high-temperature media. It is commonly installed in reactor feed lines, solvent recovery systems, polymer production units, and chemical injection loops, where space constraints, high cycle demands, and aggressive fluids require a durable, low-maintenance solution. Its robust construction and efficient sealing performance make it ideal for modulating or isolating flow in demanding petrochemical processes.

- Reactor Feed Lines: Provides compact, metal-seated isolation for aggressive or high-temperature chemical feeds entering reactors.

- Solvent Recovery Systems: Ensures precise flow control and erosion resistance in systems handling volatile or corrosive solvents.

- Polymer Production Units: Delivers high-cycle, low-maintenance performance in abrasive and viscous flow conditions common in polymer processing.

- Chemical Injection Loops: Offers tight shut-off and compact installation for metered injection of reactive or hazardous chemicals.

- Heat Transfer Fluid Systems: Handles thermal cycling and elevated temperatures with metal-to-metal sealing in secondary heating circuits.

- Utility and Skid Packages: Fits space-constrained modular systems requiring reliable, long-lasting control of process media.

La vanne GVS LOWE, avec son design compact à siège métal-métal quart de tour, est utilisée dans l’industrie pétrochimique pour un contrôle précis du débit et une fermeture fiable dans des applications impliquant des fluides abrasifs, corrosifs ou à haute température. Elle est couramment installée sur les lignes d’alimentation de réacteurs, les systèmes de récupération de solvants, les unités de production de polymères et les boucles d’injection chimique, là où les espaces exigus, les cycles élevés et les fluides agressifs exigent une solution durable et nécessitant peu d’entretien. Sa robustesse et ses performances d’étanchéité en font le choix idéal pour le réglage ou l’isolement du débit dans les processus pétrochimiques exigeants.

- Lignes d’alimentation de réacteurs : Isolation compacte et siège métallique pour les aliments chimiques agressifs ou à haute température des réacteurs.

- Systèmes de récupération de solvants : Contrôle précis du débit et résistance à l’érosion pour les solvants volatils ou corrosifs.

- Unités de production de polymères : Excellentes performances à cycles élevés et faible maintenance dans les flux abrasifs ou visqueux des procédés polymères.

- Boucles d’injection chimique : Coupure étanche et installation compacte pour l’injection contrôlée de produits réactifs ou dangereux.

- Systèmes de fluide caloporteur : Supporte les cycles thermiques et températures élevées grâce à l’étanchéité métal-métal dans les circuits de chauffage secondaires.

- Utilités et skids modulaires : Parfaite pour les systèmes modulaires exigus nécessitant un contrôle fiable et durable des fluides de process.

The GVS LOWE valve is used in the food and beverage industry for compact, durable flow control in applications involving abrasive, high-temperature, or high-cycle service where metal-to-metal sealing is preferred. Its low-torque, quarter-turn design makes it well-suited for steam and condensate lines, roasting and drying systems, sugar processing, and brewery or distillery heating circuits, where reliable shut-off and minimal maintenance are essential. The robust construction ensures long service life even in demanding sanitary environments, while its compact footprint allows installation in space-constrained processing lines without compromising performance.

- Steam and Condensate Lines: Provide durable, metal-seated shut-off for steam supply and condensate return in cooking, pasteurization, and sterilization systems.

- Roasting and Drying Systems: Ensure reliable isolation in high-temperature air or gas lines for coffee roasting, nut drying, or grain processing.

- Sugar Processing: Handle abrasive sugar crystal slurries and high-temperature syrups with long-lasting, erosion-resistant sealing.

- Brewery Heating Circuits: Control hot water or steam flow to brewing kettles and heat exchangers for precise temperature management.

- Distillery Heating Systems: Provide tight shut-off in steam or hot fluid lines feeding stills and mash tuns under high-cycle operation.

- Food Processing Utilities: Fit into compact, hygienic utility lines where robust performance is required in space-limited installations.

La vanne GVS LOWE est utilisée dans l’industrie agroalimentaire pour un contrôle de débit compact et durable dans des applications impliquant des services abrasifs, à haute température ou à cycles élevés, où une étanchéité métal-métal est préférée. Sa conception quart de tour à faible couple la rend idéale pour les lignes de vapeur et de condensat, les systèmes de torréfaction et de séchage, la transformation du sucre, ainsi que les circuits de chauffage de brasseries ou de distilleries, où une fermeture fiable et un entretien minimal sont essentiels. Sa construction robuste assure une longue durée de vie même dans des environnements sanitaires exigeants, tandis que son encombrement réduit permet une installation dans des lignes de production à espace limité sans compromettre les performances.

- Lignes de vapeur et condensat : Fermeture durable à siège métallique pour l’alimentation en vapeur et le retour de condensat dans les systèmes de cuisson, pasteurisation et stérilisation.

- Systèmes de torréfaction et séchage : Isolation fiable dans les lignes d’air ou de gaz à haute température pour la torréfaction du café, le séchage des noix ou la transformation des céréales.

- Transformation du sucre : Gestion des boues de cristaux de sucre abrasifs et des sirops à haute température avec une étanchéité résistante à l’érosion.

- Circuits de chauffage de brasserie : Contrôle du flux d’eau chaude ou de vapeur vers les cuves de brassage et les échangeurs thermiques pour une gestion précise de la température.

- Systèmes de chauffage de distillerie : Coupure étanche dans les lignes de vapeur ou de fluide chaud alimentant les alambics et cuves de brassage en fonctionnement à cycles élevés.

- Utilités en transformation alimentaire : Adaptée aux lignes utilitaires compactes et hygiéniques où une performance robuste est nécessaire dans un espace réduit.

GVS LOWE Valves are used in the automotive industry for compact, high-performance flow control in systems requiring durable, metal-to-metal sealing under demanding conditions. Their robust, low-torque quarter-turn design makes them ideal for applications such as engine test stands, cooling and thermal management circuits, fuel and exhaust gas handling, and automated fluid filling systems. With a compact footprint and reliable sealing across a wide range of temperatures and pressures, LOWE valves are well-suited for precision fluid control, high-cycle operation, and tight space constraints commonly found in automotive manufacturing and testing environments.

- Engine Test Stands: Provide precise, repeatable flow control for fuel, coolant, or oil circuits under high-cycle testing conditions.

- Cooling and Thermal Management: Deliver reliable isolation and modulation of coolant flow in engine, battery, or HVAC thermal systems.

- Fuel and Exhaust Gas Handling: Ensure tight shut-off in compact systems managing liquid fuels or exhaust gas recirculation (EGR).

- Automated Fluid Filling: Control the flow of transmission fluids, oils, or coolants in robotic vehicle assembly lines.

- Brake and Powertrain Benches: Regulate hydraulic or pneumatic flows in high-pressure, repetitive test environments with long valve life.

- Emission Control Systems: Operate in harsh environments to manage vapor or exhaust flow with corrosion- and heat-resistant sealing.

Les vannes GVS LOWE sont utilisées dans l’industrie automobile pour un contrôle de débit compact et performant dans des systèmes nécessitant une étanchéité métal-métal durable dans des conditions exigeantes. Leur conception robuste quart de tour à faible couple les rend idéales pour des applications telles que les bancs d’essai moteur, les circuits de gestion thermique, la manipulation des carburants et des gaz d’échappement, et les systèmes automatisés de remplissage de fluides. Avec un encombrement réduit et une étanchéité fiable sur une large plage de températures et de pressions, elles conviennent parfaitement au contrôle précis des fluides, aux opérations à cycles élevés et aux espaces restreints courants dans la fabrication et les essais automobiles.

- Bancs d’essai moteur : Contrôle précis et reproductible du débit de carburant, de liquide de refroidissement ou d’huile dans des conditions d’essai à cycles élevés.

- Gestion thermique : Isolation fiable et modulation du débit de liquide de refroidissement dans les systèmes thermiques de moteur, batterie ou CVC.

- Manipulation des carburants et gaz d’échappement : Fermeture étanche dans les systèmes compacts gérant les carburants liquides ou la recirculation des gaz d’échappement (EGR).

- Remplissage automatisé des fluides : Contrôle du débit des huiles, liquides de transmission ou de refroidissement dans les lignes d’assemblage robotisées.

- Bancs d’essai de freinage et transmission : Régulation des flux hydrauliques ou pneumatiques dans des environnements de test à haute pression et cycles répétés.

- Systèmes de contrôle des émissions : Fonctionnement en environnement sévère pour gérer les flux de vapeur ou de gaz d’échappement avec une étanchéité résistante à la corrosion et à la chaleur.