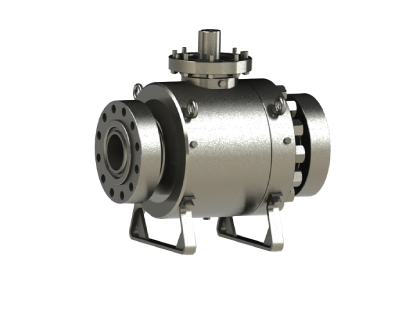

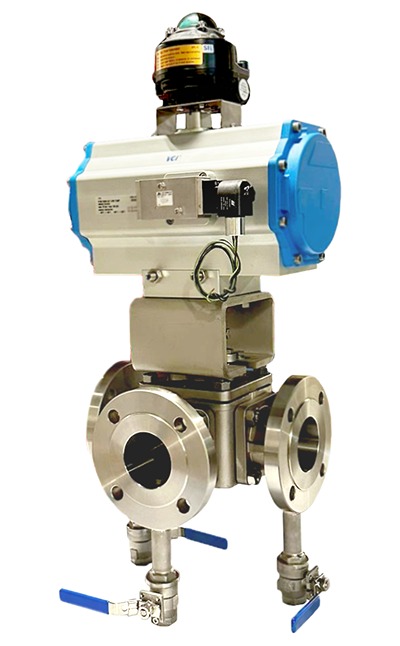

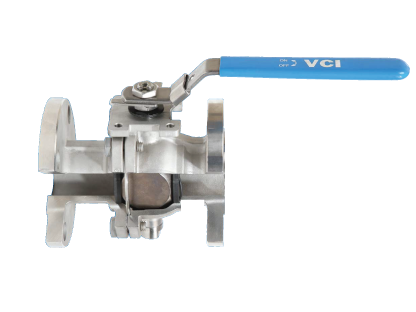

GVS Trunnion-Mounted Cryogenic Ball Valves are used in Oil & Gas applications involving liquefied gases such as LNG (liquefied natural gas), LPG, and liquid nitrogen, where reliable shut-off at extremely low temperatures is critical. These valves are commonly installed in liquefaction plants, LNG export terminals, storage tanks, and marine loading arms, where they handle cryogenic fluids at high pressures while maintaining sealing integrity and minimizing thermal contraction risks. Designed with extended bonnets and low-temperature materials, they ensure safe, long-term operation in systems requiring bubble-tight isolation, automation, and low fugitive emissions under cryogenic conditions.

- Liquefaction Plants: Control the flow of natural gas during the cooling and liquefaction process, ensuring tight shut-off at cryogenic temperatures.

- LNG Export Terminals: Provide critical isolation for loading systems, ensuring safe transfer of LNG to carriers under extreme low-temperature conditions.

- Cryogenic Storage Tanks: Maintain secure shut-off and flow control at tank inlets and outlets where liquid hydrocarbons are stored below –150°C.

- Marine Loading Arms: Enable safe, automated operation during ship-to-shore LNG transfer, withstanding thermal shock and frequent cycling.

- LPG and Liquid Nitrogen Systems: Deliver reliable performance in high-pressure, cryogenic fluid service, preventing leakage and ensuring operational safety.

- LNG Regasification Terminals: Regulate and isolate LNG as it is warmed and converted back to gas, requiring materials and seals resistant to thermal cycling.

Les vannes cryogéniques à boisseau sphérique GVS, montées sur tourillon, sont utilisées dans l’Oil & Gas pour les gaz liquéfiés comme le GNL (gaz naturel liquéfié), le GPL et l’azote liquide, là où une étanchéité fiable à très basse température est indispensable. Elles sont installées dans les usines de liquéfaction, terminaux d’export GNL, cuves de stockage et bras de chargement maritime, pour manipuler des fluides cryogéniques sous haute pression tout en assurant l’intégrité du joint et en limitant les effets de contraction thermique. Dotées de bonnet rallongé et de matériaux basse température, elles assurent sécurité, automatisation et étanchéité longue durée, même sous conditions cryogéniques strictes.

- Usines de liquéfaction : Contrôle du gaz naturel durant le refroidissement et la liquéfaction, avec fermeture étanche sous température cryogénique.

- Terminaux d’export GNL : Isolation critique pour les systèmes de chargement, assurant le transfert sécurisé du GNL vers les navires, même sous température extrême.

- Cuves de stockage cryogéniques : Coupure et contrôle du flux aux entrées/sorties de cuves stockant des hydrocarbures liquides sous –150°C.

- Bras de chargement maritime : Fonctionnement automatisé et sécurisé lors des transferts navire-terre, résistant aux chocs thermiques et cycles fréquents.

- Systèmes GPL et azote liquide : Performance fiable en service cryogénique haute pression, empêchant toute fuite et garantissant la sécurité opérationnelle.

- Terminaux de regazéification GNL : Régulation et isolation du GNL lors de sa re-vaporisation, avec des matériaux et joints adaptés au cyclage thermique.

GVS Cryogenic Trunnion Mounted Ball Valves are used in the energy industry for reliable isolation and flow control of liquefied gases such as LNG, liquid nitrogen, and liquid hydrogen under extreme low-temperature conditions. These valves are commonly installed in LNG liquefaction and regasification terminals, cryogenic storage facilities, gas-fired power plants, and energy export infrastructure, where their extended bonnets and low-temperature materials ensure safe, leak-tight performance. Designed for high-pressure and large-diameter service, they are ideal for automated systems requiring durability, thermal stability, and compliance with stringent safety standards in critical energy operations.

- LNG Liquefaction Terminals: Provide secure, low-temperature isolation of liquefied natural gas during processing and transfer to storage or export systems.

- LNG Regasification Terminals: Control the flow of LNG as it is converted back to gas, ensuring tight shut-off under cryogenic and high-pressure conditions.

- Cryogenic Storage Facilities: Maintain reliable sealing at the inlet and outlet of storage tanks holding liquefied gases such as LNG, liquid nitrogen, or hydrogen.

- Gas-Fired Power Plants: Manage cryogenic fuel delivery to turbines, offering precise control and safe operation in cold, high-pressure environments.

- Energy Export Infrastructure: Ensure dependable, fire-safe isolation of cryogenic products in marine loading arms and transfer lines for international LNG shipment.

- Hydrogen Energy Systems: Support safe flow control in emerging clean energy applications involving liquid hydrogen storage and distribution.

Les vannes cryogéniques à boisseau sphérique GVS montées sur tourillon sont utilisées dans l’énergie pour l’isolement et le contrôle fiable des gaz liquéfiés (GNL, azote liquide, hydrogène liquide) sous conditions de très basse température. Elles sont installées dans les terminaux de liquéfaction/regazéification GNL, installations de stockage cryogénique, centrales à gaz et infrastructures d’exportation, où le bonnet rallongé et les matériaux spéciaux garantissent l’étanchéité en toute sécurité. Conçues pour les services haute pression et grand diamètre, elles sont idéales en automatisation, stabilité thermique et respect des standards de sécurité dans les opérations critiques.

- Terminaux de liquéfaction GNL : Isolation sûre à basse température du gaz naturel liquéfié lors du traitement et transfert vers stockage ou exportation.

- Terminaux de regazéification GNL : Contrôle du flux de GNL lors de sa transformation en gaz, avec fermeture étanche en conditions cryogéniques et haute pression.

- Installations de stockage cryogénique : Étanchéité fiable à l’entrée et sortie de cuves pour GNL, azote liquide ou hydrogène.

- Centrales à gaz : Gestion du carburant cryogénique vers turbines, contrôle précis et sécurité sous froid et haute pression.

- Infrastructures d’export d’énergie : Isolation coupe-feu des produits cryogéniques dans les bras de chargement maritimes et lignes de transfert pour l’export international.

- Systèmes hydrogène énergie : Contrôle sécurisé du flux pour le stockage/distribution d’hydrogène liquide dans les applications énergie propre.