Benefits

The TruTorq® MGO actuator coupling was designed to allow all TruTorq actuators to work perfectly with any valve or mechanism that requires a quarter turn.

They are even a perfect combination with all other brands of pneumatic actuators.

MGOs are made with high quality materials and precise machining to guarantee maximum service and reliability.

MGO is mounted directly on the actuator for a low profile design.

The actuator contains two independent stroke stops +/- 5 ° for the opening and closing position.

The release handle is held firmly in place by a spring-loaded locking pin to ensure the engagement or disengagement of the gear.

The body is made of solid anodized aluminum (other treatments available on request).

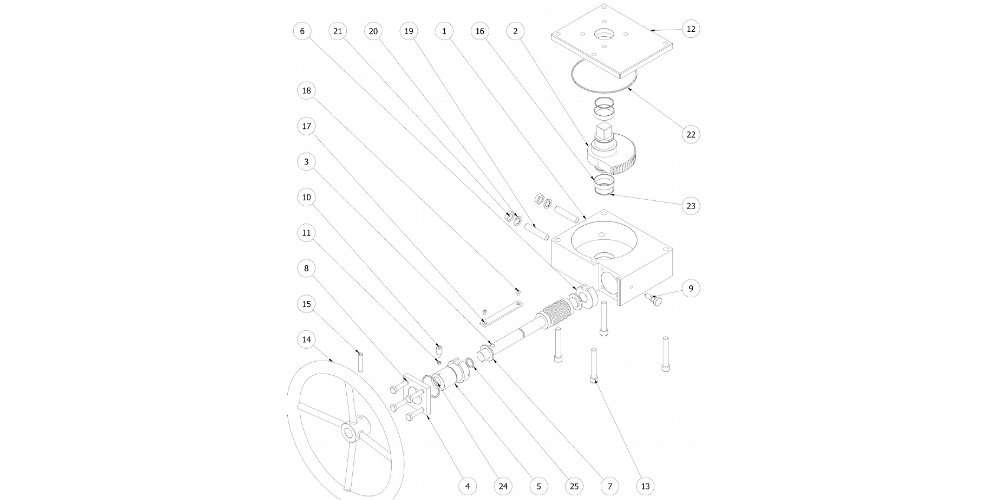

Components

| Element | Description | Material | Treatment | Quantity |

|---|---|---|---|---|

| 1 | Gear Housing | Aluminum | Anodized | 1 |

| 2 | Worm Wheel | Carbon Steel | Phosphated | 1 |

| 3 | Worm Gear | Carbon Steel | Phosphated | 1 |

| 4 | Closing Flange | Aluminum | Anodized | 1 |

| 5 | Front Sleeve | Carbon Steel | Phosphated | 1 |

| 6 | Back Sleeve | Carbon Steel | Phosphated | 1 |

| 7 | Rolling Bearing | Stainless Steel | — | 2 |

| 8 | Closing Flange Screws | Stainless Steel | — | 4 |

| 9 | Engaging Lever | Polymer/Stainless Steel | — | 1 |

| 10 | Clutching/Decluching Lever | Polymer/Stainless Steel | — | 1 |

| 11 | Nuts | Stainless Steel | — | 1 |

| 12 | Cover | Aluminum | Anodized | 1 |

| 13 | Fixing Cover Screws | Stainless Steel | — | 4 |

| 14 | Handwheel | Steel | Polyester painted | 1 |

| 15 | Handwheel pin | Steel | — | 1 |

| 16 | Worm wheel bearing | POM | — | 2 |

| 17 | Sleeves connection plate | Stainless Steel | — | 1 |

| 18 | Plate screws | Stainless Steel | — | 4 |

| 19 | End stop adjustment screws | Stainless Steel | — | 2 |

| 20 | Spring Washer | Stainless Steel | — | 2 |

| 21 | Nuts | Stainless Steel | — | 2 |

| 22 | Cover O-Ring | NBR | — | 1 |

| 23 | Worm Wheel O-Ring | NBR | — | 2 |

| 24 | Flange O-Ring | NBR | — | 1 |

| 25 | Worm Gear O-Ring | NBR | — | 1 |

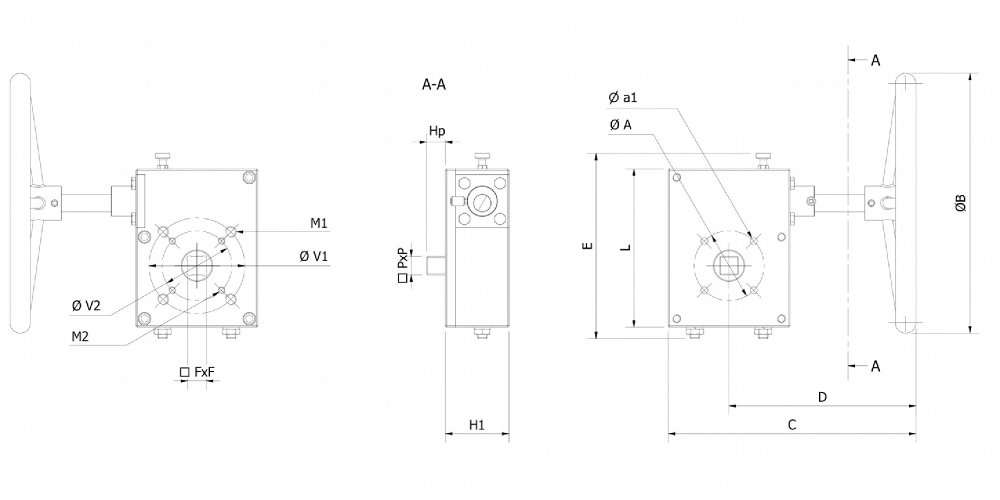

Dimensions

Metric (mm)

| Size | C | D | E | L | H1 | Hp | Valves | Actuator | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ISO5211 | F | ØV1 | M1 | ØV2 | M2 | ISO5211 | P | ØA | Øa1 | |||||||

| MG0300 | 229 | 180 | 179 | 140 | 68 | 18,2 | F05/F07 | 17 | 70 | M8 | 50 | M6 | F05 | 17 | 50 | 6,5 |

| MG0600 | 279 | 205 | 229 | 193 | 68 | 23,2 | F07/F10 | 22 | 102 | M10 | 70 | M8 | F10 | 22 | 102 | 10,5 |

| MG01200 | 362 | 273 | 272 | 232 | 93 | 27,3 | F10/F14 | 36 | 140 | M16 | 102 | M10 | F10 | 36 | 102 | 10,5 |

| MG02000 | 432 | 308 | 339 | 295 | 93 | 45 | F10/F14 | 46 | 140 | M16 | 102 | M10 | F10 | 46 | 102 | 10,5 |

Technical Data

| Size | Input torque (Nm) | Output torque (Nm) | Weight (Kg) | Manual wheel (mm) |

|---|---|---|---|---|

| MG0300 | 35 | 300 | 4,3 | 200 |

| MG0600 | 45 | 600 | 7,7 | 250 |

| MG01200 | 70 | 1200 | 15,8 | 350 |

| MG02000 | 70 | 2000 | 24,2 | 350 |

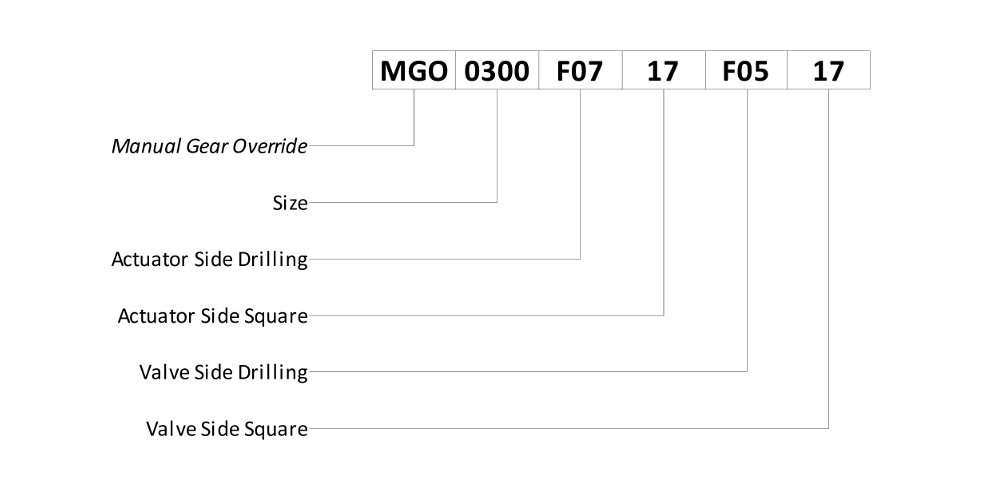

Numbers

| Size | Actuator | Valve | ||

|---|---|---|---|---|

| Drilling | Square | Drilling | Square | |

| 0300 | F05 | 14 | F05 | 14 |

| F07 | 17 | 17 | ||

| 22 | 22 | |||

| 0600 | F07 | 17 | F07 | 17 |

| F10 | 22 | F12 | 22 | |

| 27 | 27 | |||

| 1200 | F07 | 17 | F10 | 22 |

| F10 | 22 | F12 | 27 | |

| F12 | 27 | 36 | ||

| 2000 | F10 | 22 | F10 | 22 |

| F12 | 27 | F12 | 27 | |

| F14 | 36 | F14 | 36 | |

| F16 | 46 | F16 | 46 | |