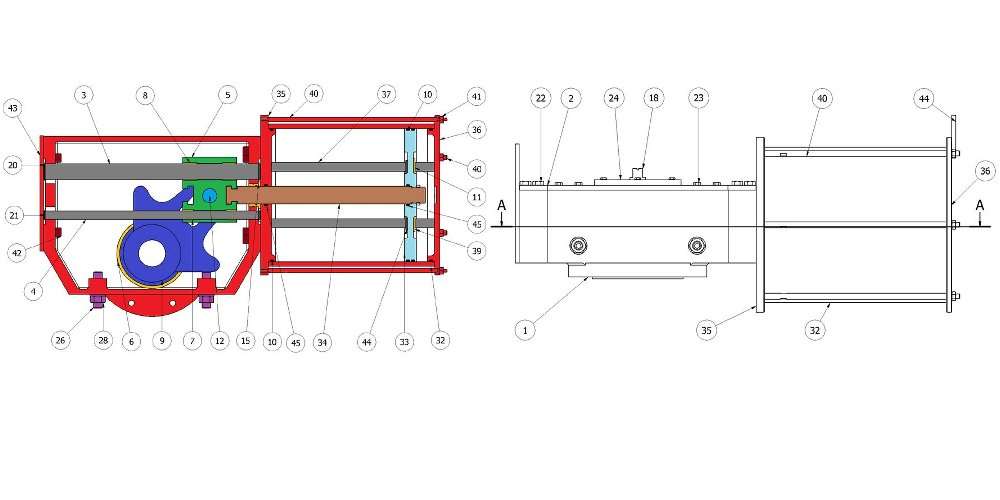

Components

Body

- Made of welded carbon steel.

- Bidirectional double-stop adjustments with integrated adjustment, which allow adjustment from 85c to 95c. Modulated and subjected to a pressurized area for safe operation.

- Actuator made of welded steel, equipped with two self-lubricating bronze bearings to improve alignment.

- Steel pin, equipped with bearings with two guide bushes, to ensure symmetrical motion. Two chromed steel bars guide the actuator during the travel across a steel carriage.

Hydraulic Cylinder

- Made of carbon steel.

- Fully welded for better pressure resistance.

- Maximum pressure 210 bar.

- Double Acting (DA) available in single or double cylinder.

Spring cylinder

- The spring is located inside the steel cylinder.

- The spring is sized with respect to the oil supply pressure.

- The spring cylinder is welded to the flange fixed to the central body.

- The design allows the cylinder to be completely removed with the compressed spring safely inside.

Surface treatments

- Actuator and carriage are phosphate-plated;

- The entire external surface of the actuator is sand-blasted and painted with epoxy powder, RAL3020 as per standard, another color on request.

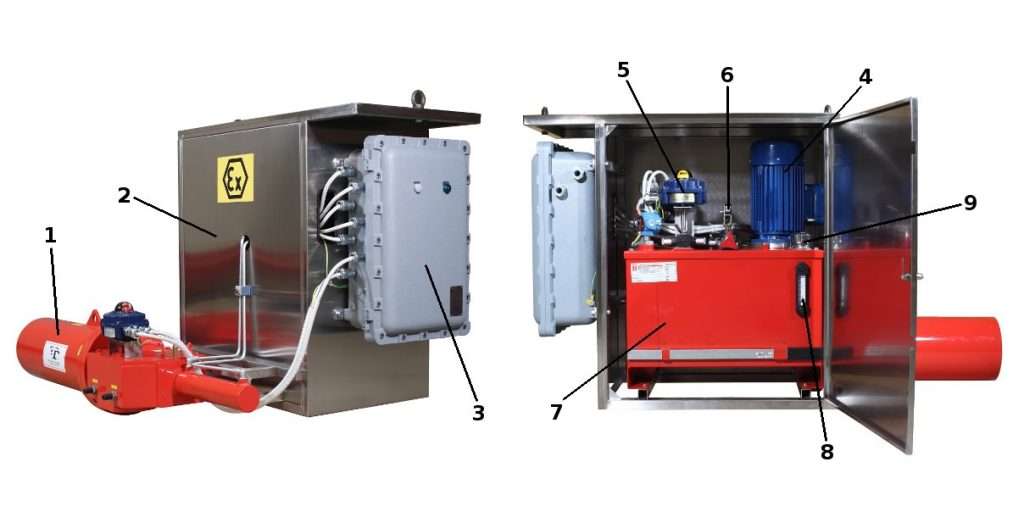

Power Pack

- Functional Power Pack Unit.

- All important components (motor, pump, hydraulic solenoid valve, hydraulic tank, etc.) are protected and included in a steel box (stainless steel on request).

- Manual override of the pump installed in the steel box.

- The Power Pack design can be realized according to customer dimensional needs.

Parts

| Element | Description | Options |

|---|---|---|

| 1 | Hydraulic Actuator | Double Acting / Spring Return |

| 2 | Power Pack | Steel / Stainless Steel |

| 3 | Electronic Cabin | STD / Exd |

| 4 | Motor | STD / Exd |

| 5 | Hand Pump Lever Switch | STD / Exd |

| 6 | Hand Pump | / |

| 7 | Hydraulic Reservoir | / |

| 8 | Oil Level Indicator | STD / Exd |

| 9 | Oil Reservoir Filling | / |